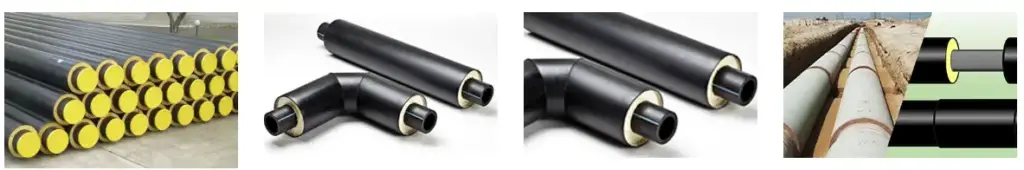

Pre-insulated pipes are a specialized type of pipe system that includes three main components: a carrier pipe (also called the service pipe or inner pipe), insulation material, and an outer casing. These pipes are specifically designed for efficiently transporting fluids like hot water, steam, or chilled liquids while ensuring excellent thermal insulation. The insulation securely connects the carrier pipe and the casing. They are also referred to as bonded pipes or insulated pipes.

The service pipe, found in pre-insulated pipes, is typically constructed using materials such as steel, copper, or plastic, depending on the specific requirements and application. Its main purpose is to carry the fluid being transported through the pipe. One of the most common applications for pre-insulated pipes is district heating networks, where hot water is widely used.

To minimize heat transfer, the carrier pipe is surrounded by insulation material. This insulation material plays a crucial role in maintaining the temperature inside the service pipe. Popular choices for insulation materials in pre-insulated pipes include polyurethane foam, polyisocyanurate foam, or mineral wool. These materials possess excellent thermal properties, resulting in minimal heat loss or gain from the fluid inside the pipe. Typically, their thermal conductivity ranges from 0.024 to 0.033 W/(m·K).

The insulation material is then enclosed by an outer jacket or casing, which serves to protect the pipe assembly and provide mechanical strength. The outer jacket is commonly made from materials like high-density polyethylene (HDPE), polyvinyl chloride (PVC), or steel, selected based on the specific application and environmental conditions. In Figure 1 below, you can see some examples of typical pre-insulated pipes.

Advantages of Pre-Insulated Pipes

To Harnessing the Potential of Pre-Insulated Pipes, we need to know in details the advantages it has to offer. Pre-insulated pipes find widespread applications across industries such as district heating and cooling systems, oil and gas pipelines, and industrial process piping. Their utilization offers numerous benefits, including:

Enhanced Energy Efficiency: The insulation layer significantly reduces heat loss or gain, leading to improved energy efficiency and cost savings.

Minimized Heat Transfer: By providing excellent thermal insulation, pre-insulated pipes prevent condensation formation on the outer surface and maintain a consistent temperature for the transported fluid.

Corrosion Protection: The outer jacket acts as a protective barrier, shielding the carrier pipe from corrosion, which enhances durability, reduces maintenance requirements, and extends the overall lifespan.

Simplified Installation: Supplied in long lengths, pre-insulated pipes facilitate easier installation, minimize the need for joints, and reduce the potential for leaks or failures.

Environmental Friendliness: Through decreased energy consumption and heat loss, pre-insulated pipes contribute to environmental sustainability by reducing greenhouse gas emissions.

These pipes are available in a variety of sizes, insulation thicknesses, and configurations, ensuring adaptability to meet specific project requirements.

Establishing Quality: Codes and Standards Governing Pre-Insulated Pipes

In the realm of pre-insulated pipes for district heating systems, European standards EN 253 and EN 15698-1 serve as essential references. These standards outline specific requirements and guidelines for different types of pre-insulated pipe systems.

EN 253

This standard focuses on bonded single pipe systems designed for directly buried hot water networks. It details the assembly specifications, encompassing a steel service pipe, polyurethane thermal insulation, and a polyethylene casing.

EN 15698-1

On the other hand, EN 15698-1 addresses bonded twin pipe systems used in directly buried hot water networks. This standard provides guidance for the twin pipe configuration, which consists of steel service pipes, polyurethane thermal insulation, and a single polyethylene casing.

By adhering to these codes and standards, the quality and performance of pre-insulated pipe systems can be assured, enabling safe and efficient operations within district heating networks.

Applications of Pre-Insulated Pipes

In addition to their widespread use in district heating and cooling networks, pre-insulated pipes have found applications across diverse industries. These include:

- oil and gas,

- food processing,

- water treatment,

- wineries,

- chemical industries,

- infrastructure and utility projects,

- pharmaceuticals, and more.

According to market research, the pre-insulated pipe market is projected to experience significant growth with a Compounded Annual Growth Rate (CAGR) of 9.8% in the coming years. This surge can be attributed to the implementation of stringent regulations aimed at reducing carbon footprints and enhancing energy efficiency.

As industries seek sustainable and energy-efficient solutions, pre-insulated pipes have emerged as a reliable choice. Their ability to minimize heat loss, provide corrosion protection, and ensure efficient fluid transportation positions them as a key component in achieving environmental goals while maintaining operational excellence.

Specifications of Pre-insulated Pipes

When specifying pre-insulated pipes for a project, ensuring clear and detailed information is crucial to meet the required specifications. Consider the following key factors:

Fluid Type and Temperature: Clearly specifying the type of fluid (e.g., hot water, steam, chilled water) and the desired operating temperature range. This information helps determine the appropriate insulation material and thickness.

Pipe Diameter and Material: Specifying the required pipe diameter and material for the carrier pipe, considering factors like pressure rating, corrosion resistance, and project-specific needs.

Insulation Thickness: Determining the necessary insulation thickness based on heat loss/gain, ambient temperature, and energy efficiency goals. Consider the thermal conductivity of the insulation material and the desired thermal resistance (R-value).

Casing Material: Specify the outer jacket material based on environmental conditions, UV resistance, and mechanical strength requirements. Options may include HDPE, PVC, or steel.

Pipe Length: Specify the desired lengths of pre-insulated pipe sections or coils, considering installation efficiency and joint reduction. Common lengths are 6 meters, 12 meters, or 16 meters, with burial depths typically ranging from 0.6 to 1.2 meters.

Standards and Certifications: Identify specific standards or certifications that the pre-insulated pipes must meet to comply with industry or regional regulations.

Accessories and Additional Requirements: Determining if additional accessories like fittings, valves, expansion joints, or heat tracing elements are needed. Specify any special requirements for pipe connections or insulation joints.

Project-Specific Considerations: Providing any project-specific requirements, such as seismic resistance, fire resistance, or unique insulation properties.

By considering these factors and providing accurate specifications, you can ensure that the pre-insulated pipes meet your project’s needs effectively.

Pre-insulated Pipe Manufacturers

The pre-insulated pipe market is served by several reputable manufacturers worldwide. Here are some well-known companies in this field:

- Uponor Corporation (Finland)

- Logstor (Denmark)

- Perma-Pipe International Holdings, Inc. (United States)

- Georg Fischer Piping Systems Ltd. (Switzerland)

- Isoplus Fernwärmetechnik GmbH (Germany)

- Aquatherm GmbH (Germany)

- BRUGG Rohrsysteme GmbH (Switzerland)

- Thermaflex International (Netherlands)

- Huntsman Corporation (United States)

- Kooltherm Pipe Insulation (United Kingdom)

- Microflex Preinsulated Systems (Italy)

- CPV Ltd. (United Kingdom)

- Flexalen by Thermaflex (Netherlands)

- SIMONA AG (Germany)

- Rovanco Piping Systems (United States)

These manufacturers specialize in producing high-quality pre-insulated pipes and offer a diverse range of products to cater to various industrial and commercial needs. However, it’s important to note that product availability may vary depending on the region. It’s recommended to conduct thorough research and consult with local suppliers to ensure the selection of the most suitable pre-insulated pipes for specific project requirements.