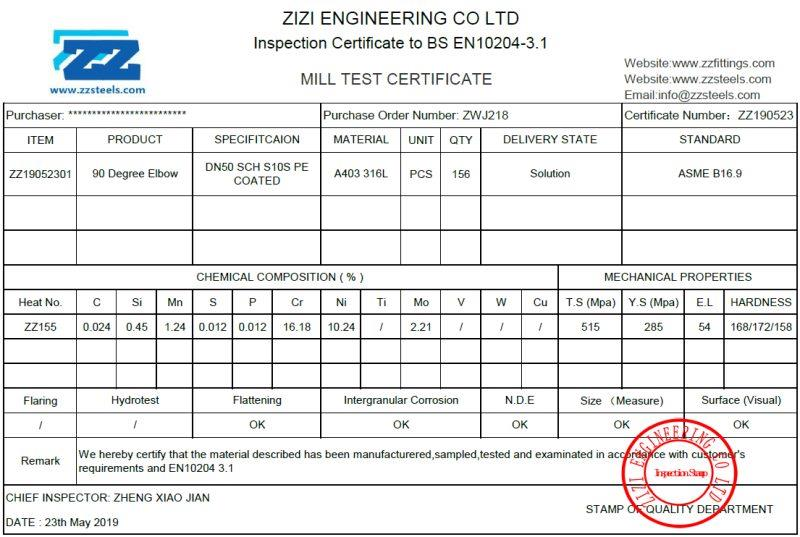

Understanding Advantages of Material Test Certificates (MTCs): Types 2.1, 2.2, 3.1, 3.2

Material Test Certificate, also known as Mill Test Certificate (MTC), is a popular quality assurance document used in the metals industry. While purchasing steel pipes, plates, bars, or other steel materials, the manufacturer provides the material test certificate along with the products that certify the material’s technical specifications. It covers parameters like chemical composition, manufacturing…