In the vast and dynamic field of ocean engineering, numerous technologies and components work in harmony to ensure the safety, efficiency, and functionality of maritime operations. Among these, modulating valves stand out as pivotal devices that regulate fluid flow in various marine systems. Though often overlooked, these valves play a critical role in maintaining the delicate balance required for the smooth operation of oceanic vessels and offshore platforms. This blog delves into the significance, applications, and advancements of modulating valves in ocean engineering.

Understanding Modulating Valves

Modulating valves, unlike their on/off counterparts, provide precise control over fluid flow rates by adjusting the valve position in response to control signals. These signals, typically generated by a control system, correspond to specific flow requirements, ensuring optimal performance of the system. The ability to modulate flow rates is essential in applications where fluid dynamics must be carefully managed, such as in the cooling systems of ships, ballast water management, and various hydraulic systems used in offshore platforms.

The Role of Modulating Valves in Ocean Engineering

- Ballast Water Management: Ballast water is crucial for maintaining the stability and structural integrity of ships. However, the transfer of ballast water between different marine environments can lead to the spread of invasive species, posing significant ecological threats. Modulating valves play a key role in ballast water treatment systems by regulating the flow of water through filtration and disinfection processes, ensuring compliance with international ballast water management standards.

- Cooling Systems: Marine vessels, from small fishing boats to massive cargo ships, rely on efficient cooling systems to maintain the operational temperature of engines and other critical machinery. Modulating valves control the flow of coolant, adjusting it in response to the engine’s temperature and operational load. This precise control not only enhances the efficiency of the cooling system but also prolongs the life of the machinery by preventing overheating.

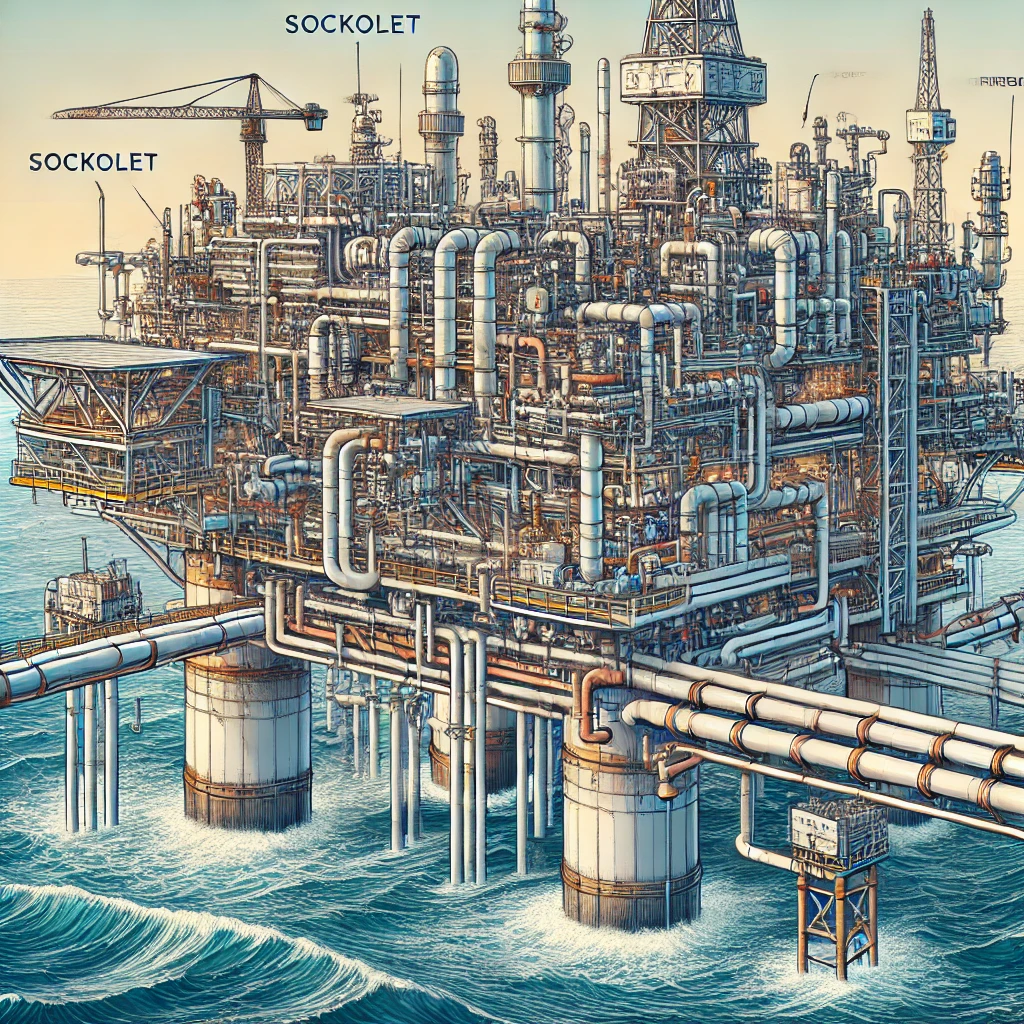

- Hydraulic Systems: Offshore platforms and subsea installations utilize complex hydraulic systems for various operations, including drilling, lifting, and positioning. Modulating valves ensure the precise control of hydraulic fluid flow, which is essential for the accurate and safe execution of these operations. The ability to modulate flow rates enhances the responsiveness and reliability of hydraulic systems, thereby improving the overall safety and efficiency of offshore activities.

Technological Advancements in Modulating Valves

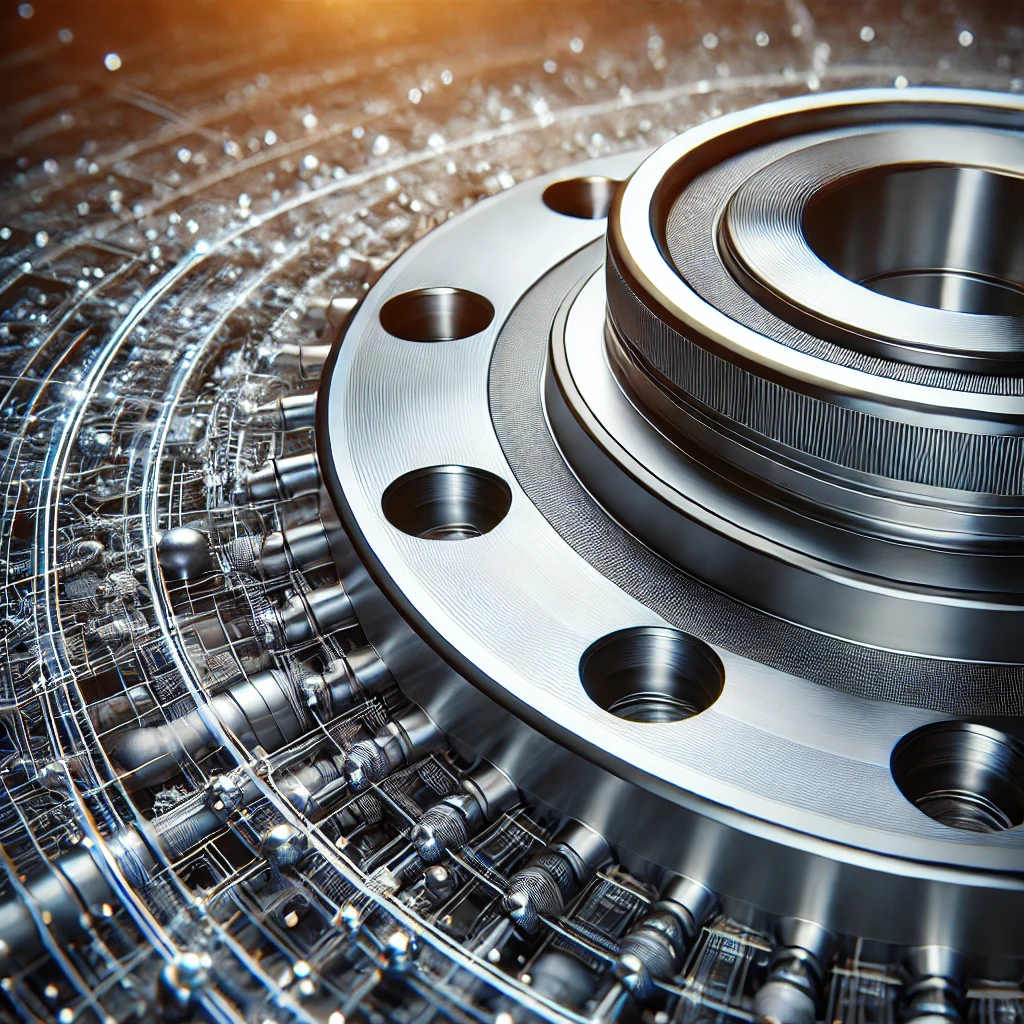

The evolution of modulating valves has been driven by advancements in materials science, control systems, and sensor technology. Modern modulating valves are equipped with smart features that enhance their functionality and integration into larger systems.

- Smart Valves: The integration of sensors and microprocessors into modulating valves has given rise to smart valves, which offer advanced diagnostic and predictive maintenance capabilities. These valves can monitor their own performance, detect anomalies, and communicate with central control systems to optimize operation and prevent failures.

- Advanced Materials: The harsh marine environment necessitates the use of materials that can withstand corrosion, pressure, and temperature extremes. Advancements in materials science have led to the development of valves made from high-performance alloys and composites, which offer superior durability and reliability in oceanic applications.

- Automation and Control: The incorporation of sophisticated control algorithms and automation technologies has significantly improved the precision and responsiveness of modulating valves. These advancements enable more accurate flow control, which is essential for the complex and dynamic conditions encountered in ocean engineering.

Case Studies: Modulating Valves in Action

Case Study 1: Ballast Water Treatment on Cargo Ships

The International Maritime Organization (IMO) has mandated strict regulations for ballast water management to prevent the spread of invasive species. A leading shipping company implemented a state-of-the-art ballast water treatment system equipped with modulating valves on its fleet of cargo ships. These valves precisely controlled the flow of ballast water through filtration and ultraviolet disinfection units, ensuring effective treatment while minimizing energy consumption. The system not only complied with IMO regulations but also enhanced the operational efficiency of the ships.

Case Study 2: Cooling System Optimization on Offshore Platforms

An offshore oil platform faced challenges with its cooling system, which was essential for maintaining the temperature of critical equipment. The platform’s engineering team installed modulating valves with advanced control capabilities to regulate the flow of seawater used for cooling. By continuously adjusting the flow rate based on real-time temperature data, the system achieved optimal cooling performance, reduced energy consumption, and extended the lifespan of the equipment.

Case Study 3: Hydraulic Control in Subsea Operations

A subsea construction company employed modulating valves in its hydraulic systems to improve the precision and safety of underwater operations. The valves’ ability to provide fine-tuned control of hydraulic fluid flow was crucial for tasks such as positioning heavy structures and operating remotely operated vehicles (ROVs). The enhanced control provided by the modulating valves resulted in more efficient and safer subsea operations.

Future Trends and Challenges

The future of modulating valves in ocean engineering is promising, with ongoing research and development focused on enhancing their performance and expanding their applications. However, several challenges remain, including the need for improved corrosion resistance, better integration with digital control systems, and the development of valves that can withstand even more extreme environmental conditions.

- Corrosion Resistance: Corrosion is a persistent challenge in marine environments. Future developments in materials science aim to create valves with superior corrosion resistance, which will further enhance their longevity and reliability in oceanic applications.

- Digital Integration: The rise of the Industrial Internet of Things (IIoT) and digitalization in marine industries necessitates the seamless integration of modulating valves with digital control systems. This integration will enable more sophisticated monitoring, control, and optimization of fluid systems on ships and offshore platforms.

- Extreme Conditions: As ocean engineering ventures into deeper and more hostile environments, there is a growing need for valves that can operate reliably under extreme pressures and temperatures. Research into new materials and design innovations will be key to addressing these challenges.

Conclusion

Modulating valves are indispensable components in the field of ocean engineering, providing the precise flow control needed for a wide range of marine applications. From ballast water management and cooling systems to hydraulic controls in offshore operations, these valves play a critical role in ensuring the efficiency, safety, and compliance of maritime systems. As technology continues to advance, the capabilities of modulating valves will only improve, offering new opportunities and solutions for the challenges faced by ocean engineers.

The ongoing development of smart valves, advanced materials, and sophisticated control systems promises a future where modulating valves will be even more integral to the success of ocean engineering projects. By understanding and leveraging the potential of these unsung heroes, the maritime industry can continue to innovate and thrive in the face of evolving demands and environmental challenges.