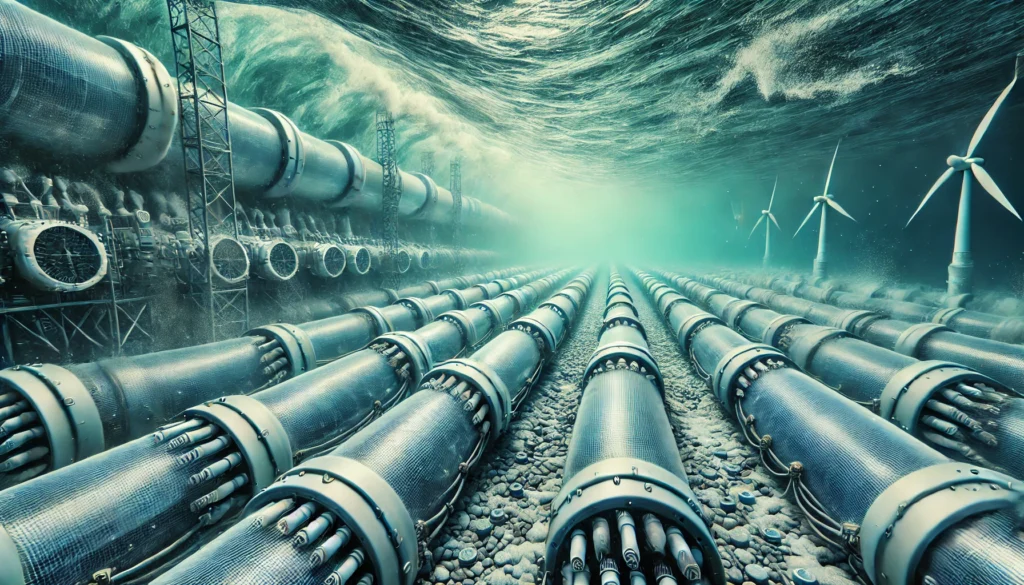

Ocean engineering is an interdisciplinary field that involves the application of engineering principles to the design, construction, and maintenance of structures and systems used in the ocean environment. This field encompasses a wide range of activities, including the development of offshore oil and gas platforms, underwater pipelines, and marine renewable energy devices. One critical component that plays a vital role in the performance and safety of these ocean engineering systems is insulation tubes. These tubes are used to protect and insulate various components from the harsh marine environment, ensuring their longevity and efficiency. In this blog, we will delve into the importance of insulation tubes in ocean engineering, explore some case studies, and highlight the challenges and advancements in this field.

The Role of Insulation Tubes in Ocean Engineering

Insulation tubes are essential for maintaining the integrity and functionality of ocean engineering systems. They serve several key purposes:

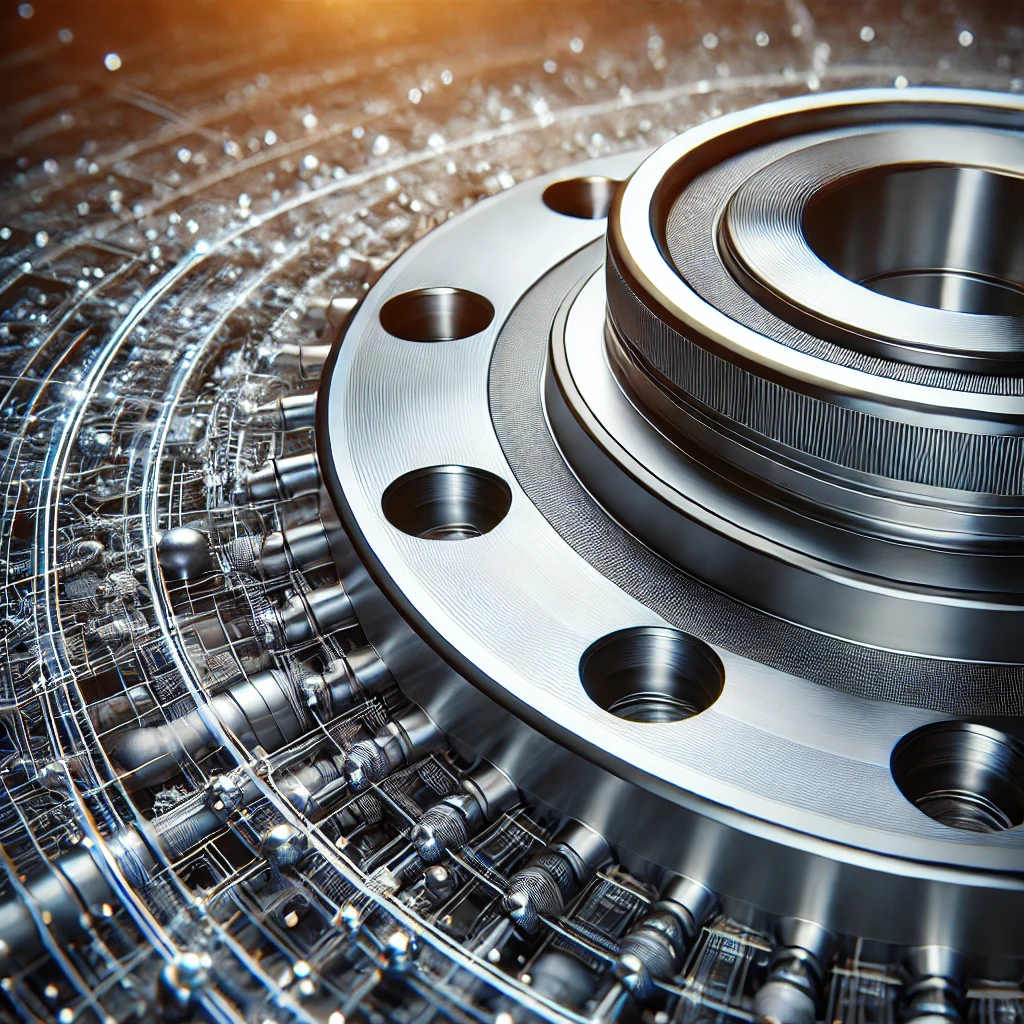

- Thermal Insulation: In deep-sea environments, temperature variations can be extreme. Insulation tubes help maintain a stable temperature for sensitive components, such as pipelines carrying oil or gas, to prevent thermal expansion and contraction that could lead to structural failures.

- Corrosion Protection: The marine environment is highly corrosive due to the presence of saltwater and other aggressive elements. Insulation tubes provide a protective barrier, reducing the risk of corrosion and extending the lifespan of the components they encase.

- Mechanical Protection: Ocean engineering systems are often subjected to high pressures, mechanical stresses, and impacts from marine life or debris. Insulation tubes offer an additional layer of mechanical protection, safeguarding critical components from damage.

- Energy Efficiency: In the case of underwater pipelines and renewable energy devices, insulation tubes help in reducing energy losses. By maintaining the desired temperature or protecting against thermal conductivity, these tubes enhance the overall energy efficiency of the system.

Case Study 1: Subsea Pipelines in Offshore Oil and Gas Industry

Background

The offshore oil and gas industry relies heavily on subsea pipelines to transport hydrocarbons from the seabed to processing facilities. These pipelines are exposed to harsh conditions, including high pressures, low temperatures, and corrosive seawater. Ensuring their integrity and performance is paramount to the safety and efficiency of offshore operations.

Insulation Solutions

One notable example is the use of advanced thermal insulation tubes in the Gorgon Project, one of the world’s largest natural gas projects located off the coast of Western Australia. The project involves the construction of a subsea pipeline system that transports natural gas from the Gorgon and Jansz-Io fields to an onshore processing facility on Barrow Island.

To protect the subsea pipelines from extreme cold temperatures and to maintain the flow of gas, a multi-layer insulation system was employed. This system included high-performance insulation tubes made from advanced materials like polyurethane foam and polypropylene. These materials provided excellent thermal insulation properties, reducing heat loss and preventing hydrate formation, which can block the flow of gas.

Results

The use of advanced insulation tubes in the Gorgon Project significantly improved the thermal efficiency of the subsea pipelines. This not only ensured the smooth flow of natural gas but also reduced the energy required for heating, leading to cost savings and enhanced operational reliability. The project demonstrated how insulation tubes can play a critical role in the success of large-scale offshore oil and gas operations.

Case Study 2: Underwater Cables for Renewable Energy

Background

Renewable energy sources, such as offshore wind farms and tidal energy systems, are becoming increasingly important in the quest for sustainable energy. These systems rely on underwater cables to transmit electricity generated at sea to onshore power grids. However, the marine environment poses significant challenges to the integrity and performance of these cables.

Insulation Solutions

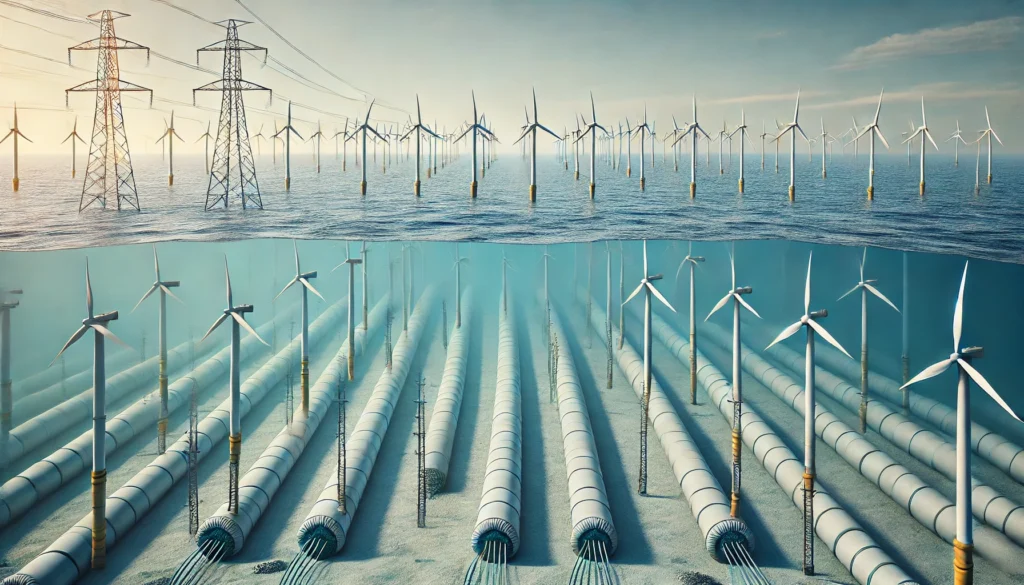

The London Array, one of the world’s largest offshore wind farms located in the Thames Estuary, serves as an excellent example of the use of insulation tubes in renewable energy projects. The wind farm consists of 175 turbines, generating enough electricity to power over half a million homes. The electricity generated by the turbines is transmitted through a network of underwater cables to an onshore substation.

To protect the underwater cables from mechanical damage and corrosion, a combination of insulation tubes and protective coatings was used. High-density polyethylene (HDPE) insulation tubes were employed to provide excellent mechanical strength and resistance to abrasion. Additionally, the cables were coated with anti-corrosion materials to prevent degradation caused by the saltwater environment.

Results

The use of insulation tubes and protective coatings in the London Array project ensured the reliability and longevity of the underwater cables. This not only minimized the risk of cable failures but also contributed to the overall efficiency and sustainability of the wind farm. The success of the London Array project highlights the importance of insulation tubes in the development of renewable energy systems in the marine environment.

Challenges and Advancements in Insulation Tube Technology

While insulation tubes have proven to be indispensable in ocean engineering, several challenges remain. These challenges drive ongoing research and development efforts to improve the performance and durability of insulation tubes.

Material Selection

One of the primary challenges is selecting the appropriate materials for insulation tubes. The materials must possess excellent thermal insulation properties, mechanical strength, and resistance to corrosion and environmental degradation. Advances in material science have led to the development of new materials, such as aerogels and nanocomposites, which offer superior insulation performance and durability.

Installation Techniques

Installing insulation tubes in the marine environment can be complex and challenging. The installation process must ensure a tight fit around the components to prevent water ingress and maintain thermal insulation. Innovations in installation techniques, such as the use of robotic systems and advanced sealing methods, are being explored to improve the efficiency and reliability of insulation tube installation.

Long-Term Performance

The long-term performance of insulation tubes is critical to the success of ocean engineering systems. Continuous exposure to harsh conditions can lead to material degradation and loss of insulation properties. Research efforts are focused on developing advanced coatings and protective layers that enhance the longevity and performance of insulation tubes.

Insulation tubes are a crucial element in ocean engineering, playing a vital role in ensuring the performance, safety, and longevity of various marine systems. Through case studies such as the Gorgon Project and the London Array, we have seen how insulation tubes contribute to the success of offshore oil and gas operations and renewable energy projects. While challenges remain, ongoing advancements in material science and installation techniques are driving the development of more efficient and durable insulation tubes. As the field of ocean engineering continues to evolve, the importance of insulation tubes in protecting and optimizing marine systems will only grow, paving the way for a more sustainable and resilient future.