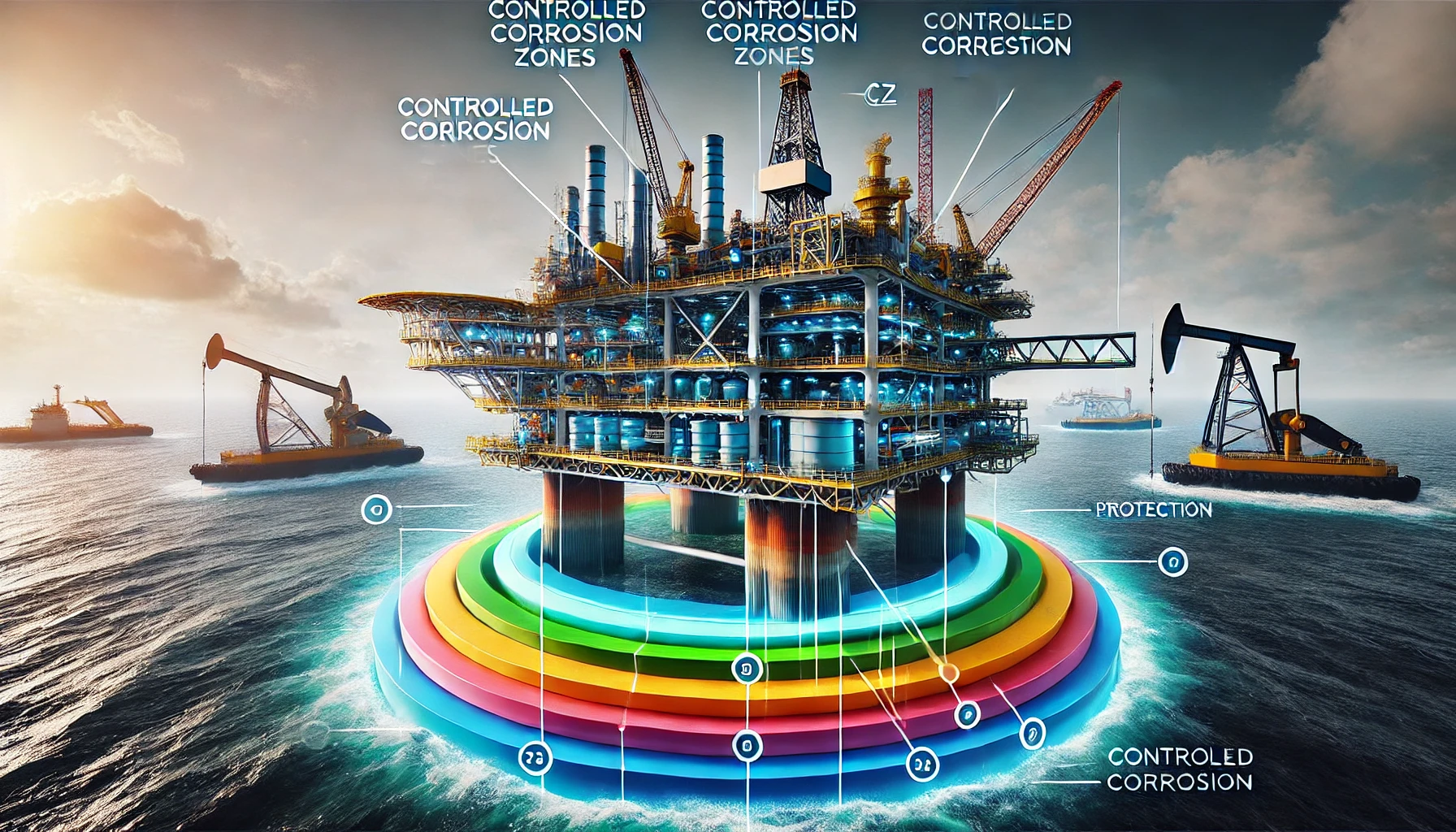

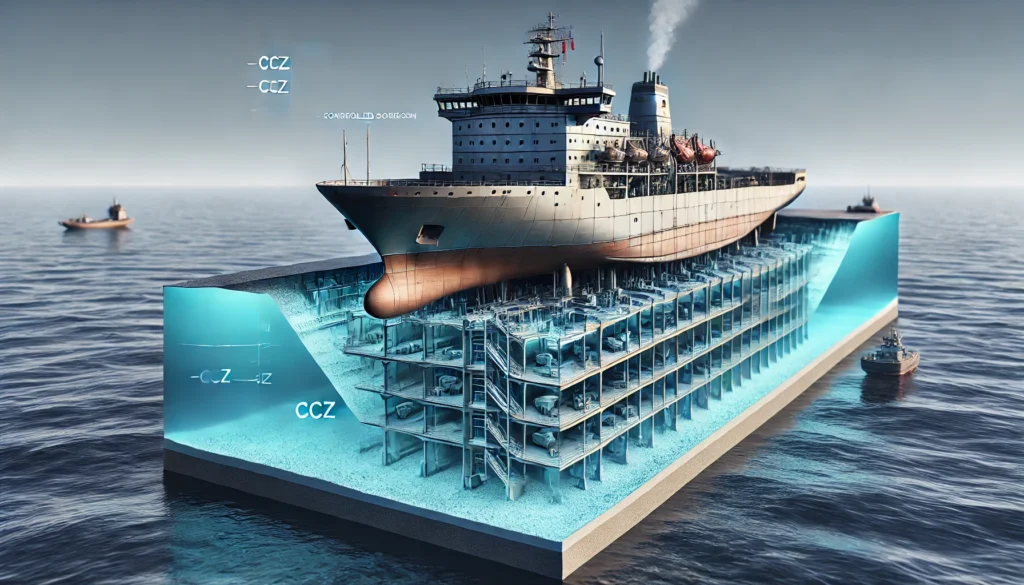

In recent years, technological advancements have significantly transformed various engineering fields, including ocean engineering. One such breakthrough is CCZ technology, a cutting-edge innovation that promises to revolutionize the way we approach challenges in marine environments. CCZ technology, short for “Controlled Corrosion Zone” technology, offers innovative solutions for corrosion management, structural integrity, and sustainability in ocean engineering projects.

The Basics of CCZ Technology

CCZ technology involves the strategic implementation of controlled corrosion zones within marine structures to manage and mitigate the detrimental effects of corrosion. Unlike traditional methods that focus solely on corrosion prevention, this technology embraces corrosion as a manageable factor. By deliberately inducing controlled corrosion in specific areas, engineers can protect critical structural components from severe damage, thereby extending the lifespan and enhancing the safety of marine infrastructure.

Applications of CCZ Technology in Ocean Engineering

Offshore Structures

Offshore structures, such as oil rigs and wind turbines, are continuously exposed to harsh marine environments. The application of CCZ in these structures can significantly enhance their durability and operational efficiency. By creating controlled corrosion zones, engineers can divert the corrosive effects away from critical load-bearing components, ensuring the longevity of these structures. This approach not only reduces maintenance costs but also minimizes the risk of catastrophic failures.

Subsea Pipelines

Subsea pipelines are vital for transporting oil and gas from offshore production sites to onshore facilities. However, these pipelines are highly susceptible to corrosion due to constant exposure to seawater. This technology provides an effective solution by establishing controlled corrosion zones along the pipeline. This technique helps in maintaining the structural integrity of the pipeline, preventing leaks and potential environmental disasters.

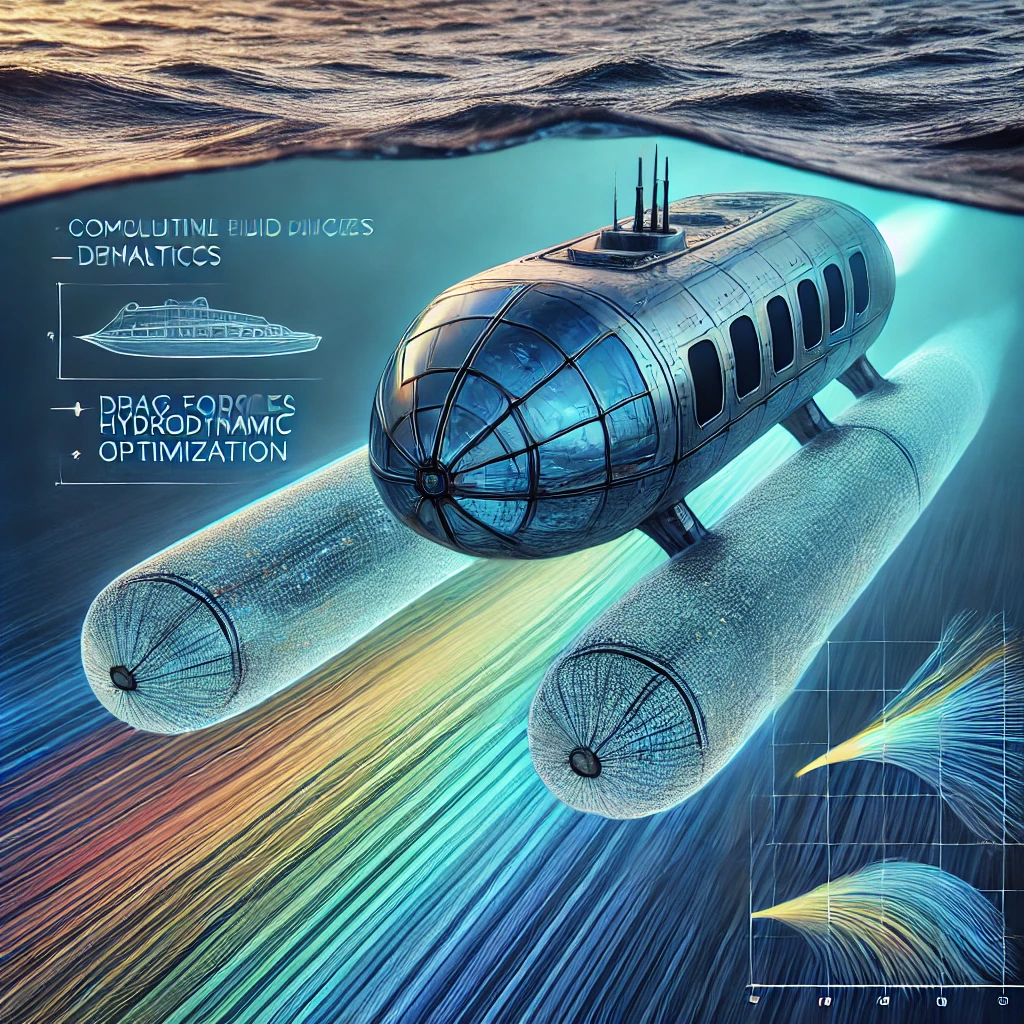

Marine Vessels

Marine vessels, including ships and submarines, face significant challenges related to corrosion. The integration in the design and maintenance of these vessels can dramatically improve their performance and lifespan. By strategically placing controlled corrosion zones, engineers can ensure that the corrosion is confined to less critical areas, safeguarding essential structural components and reducing the frequency of repairs.

Environmental Benefits of CCZ Technology

Sustainable Marine Practices

One of the significant advantages of CCZ technology is its contribution to sustainable marine practices. Traditional corrosion prevention methods often involve the use of environmentally harmful coatings and chemicals. In contrast, this reduces the need for such substances, minimizing the ecological footprint of marine engineering projects. This technology aligns with the growing emphasis on environmentally friendly practices in ocean engineering.

Reducing Material Waste

The implementation leads to a reduction in material waste. By extending the lifespan of marine structures and minimizing the need for frequent repairs and replacements, this technology promotes resource efficiency. The reduction in material waste not only benefits the environment but also results in cost savings for marine engineering projects.

Case Studies: CCZ Technology in Action

Offshore Wind Farm

A prominent offshore wind farm in Europe recently adopted CCZ technology to enhance the durability of its turbines. By incorporating controlled corrosion zones in the turbine foundations, engineers were able to mitigate the corrosive effects of seawater. This approach resulted in a significant reduction in maintenance costs and an increase in the operational lifespan of the wind farm, showcasing the practical benefits in the renewable energy projects.

Subsea Oil Pipeline

In a major subsea oil pipeline project in the Gulf of Mexico, CCZ technology played a crucial role in ensuring the pipeline’s integrity. By implementing controlled corrosion zones along the pipeline, engineers successfully managed the corrosion risk, preventing leaks and potential environmental hazards. This case study highlights the effectiveness of the technology in critical energy infrastructure.

Naval Submarine

The navy’s adoption of CCZ technology in a new class of submarines marked a significant advancement in marine defense. By strategically placing controlled corrosion zones, naval engineers enhanced the submarines’ durability and reduced the need for frequent maintenance. This innovation not only improved the operational readiness of the submarines but also contributed to significant cost savings for the navy.

Future Prospects of CCZ Technology in Ocean Engineering

Advancements in Material Science

The future of CCZ technology looks promising, with ongoing advancements in material science expected to further enhance its effectiveness. Researchers are exploring new materials and coatings that can optimize the performance of controlled corrosion zones, making this technology even more efficient and reliable. These advancements will likely expand the range of applications for the technology in ocean engineering.

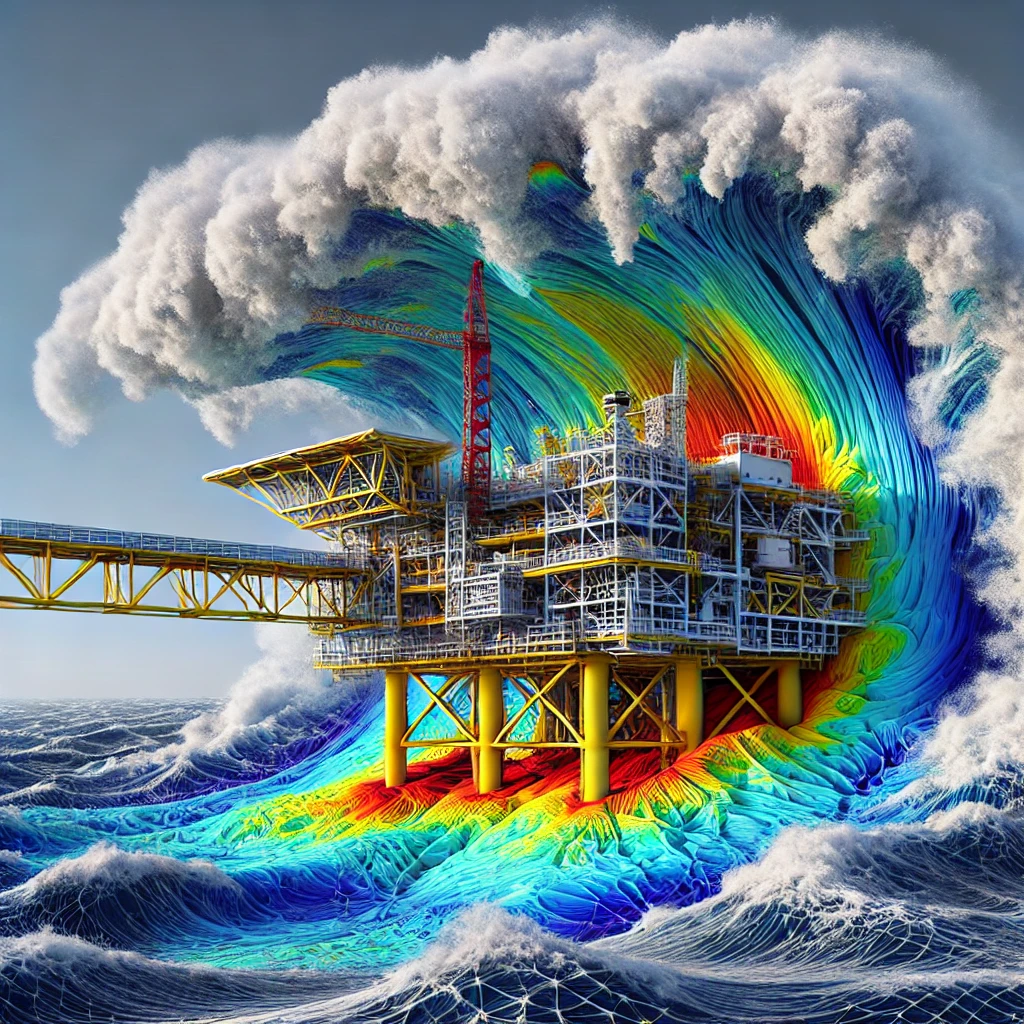

Integration with Smart Technologies

The integration of CCZ technology with smart technologies, such as sensors and monitoring systems, holds great potential for ocean engineering. By incorporating real-time monitoring and data analysis, engineers can gain valuable insights into the corrosion behavior of marine structures. This proactive approach will enable timely interventions and predictive maintenance, ensuring the long-term integrity of marine infrastructure.

Global Adoption and Standardization

As the benefits of CCZ technology become more widely recognized, there is a growing interest in its global adoption and standardization. Industry organizations and regulatory bodies are expected to develop guidelines and standards for the implementation of the technology in marine engineering projects. This standardization will facilitate the widespread adoption of this innovative technology, promoting safer and more sustainable practices in the field of ocean engineering.

Challenges and Considerations

Technical Challenges

While CCZ technology offers numerous advantages, it also presents certain technical challenges. The precise implementation of controlled corrosion zones requires careful planning and expertise. Engineers must consider factors such as the type of materials used, the specific environmental conditions, and the intended lifespan of the structure. Addressing these challenges is crucial to maximizing the benefits of the technology.

Cost Considerations

The initial cost of implementing CCZ technology may be higher compared to traditional corrosion prevention methods. However, the long-term cost savings resulting from reduced maintenance and extended lifespan of structures often outweigh the initial investment. It is essential for project stakeholders to conduct a comprehensive cost-benefit analysis to determine the feasibility and economic viability of adopting the technology.

Regulatory and Environmental Compliance

Ensuring regulatory and environmental compliance is another important consideration when implementing CCZ technology. Marine engineering projects must adhere to strict regulations and guidelines to protect marine ecosystems and ensure the safety of personnel. Engineers and project managers must work closely with regulatory authorities to ensure that the implementation of CCZ technology meets all necessary requirements.

Conclusion

CCZ technology represents a groundbreaking innovation in the field of ocean engineering, offering a novel approach to corrosion management and structural integrity. Its applications in offshore structures, subsea pipelines, and marine vessels demonstrate its versatility and effectiveness. The environmental benefits, including sustainable marine practices and reduced material waste, further highlight the significance of CCZ technology in promoting a greener and more efficient approach to ocean engineering.

As advancements in material science and smart technologies continue to evolve, the future of CCZ technology looks promising. The global adoption and standardization of this technology will play a crucial role in shaping the future of ocean engineering, ensuring safer, more durable, and environmentally friendly marine infrastructure. While challenges remain, the potential benefits of CCZ technology make it a valuable asset in addressing the complex challenges of the marine environment.

In conclusion, the integration of CCZ technology in ocean engineering marks a significant milestone in the quest for innovative and sustainable solutions. Its ability to manage and mitigate corrosion in a controlled manner paves the way for a new era of marine infrastructure, where safety, durability, and environmental responsibility are paramount. As we continue to explore the vast potential of CCZ technology, its impact on ocean engineering is set to be profound and far-reaching.