In refineries and oil and gas plants, “fired equipment” refers to the equipment used for combustion of fuel to generate heat or energy. This includes furnaces, boilers, heaters, and similar devices. Fired equipment is essential in these facilities as it provides the necessary heat and energy for processes like crude oil distillation, fluid catalytic cracking, hydro-cracking, reforming, and other refining operations. It is also used for power generation, steam production, and heating purposes within the plant.

Fired equipment can utilize various types of fuel depending on their design and specific requirements. Common fuel options include natural gas, oil, coal, and even waste products like refinery gases or residual fuels.

Safety is a paramount concern when dealing with fired equipment due to the potential risks associated with handling and combustion of flammable fuels. To ensure safe and efficient operation in refineries and oil and gas plants, several measures are implemented. These include proper equipment design, installation, maintenance, and monitoring. Safety devices, flame detectors, control systems, and regular inspections are employed to prevent accidents and comply with industry standards and regulations. By prioritizing safety, these facilities aim to minimize risks and maintain a secure working environment.

Types of Fired Equipment

In refineries and oil and gas plants, there are various types of fired equipment commonly used. Let’s explore some examples:

Furnaces:

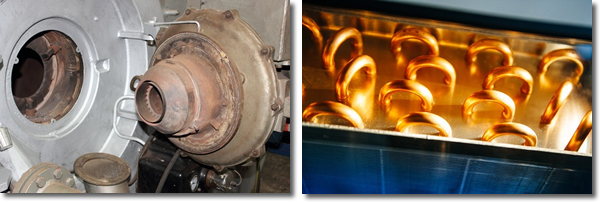

Furnaces are utilized for heating purposes in processes like crude oil heating, distillation, reforming, cracking, and others. They transfer heat to materials through conduction and convection. Furnaces can have different configurations, such as box, cylindrical, radiant, or tubular.

Boilers:

Boilers are closed vessels that generate steam by combusting fuel. This high-pressure steam is used for power generation, process heating, and other applications. Boilers find applications in central heating systems, industrial processes, power plants, and more.

Fired Heaters:

Similar to furnaces, fired heaters heat fluids or gases in the refining and petrochemical industry. They are categorized based on the type of fluid being heated, such as crude oil heaters, process heaters, thermal fluid heaters, or steam superheaters.

Incinerators:

Incinerators are specialized equipment used for the combustion of waste materials generated during refining or petrochemical processes. They help in safe waste disposal while minimizing environmental impact. Other than waste disposal, incinerators can also be used to produce electricity by burning natural gas or biofuels.

Flares:

Flares are safety devices designed to burn off excess or unwanted gases during emergency or upset conditions. They ensure the safe disposal of gases that cannot be recovered or recycled, making them an essential safety feature in refineries and petrochemical plants

Thermal Oxidizers:

Thermal oxidizers are used to control emissions of volatile organic compounds (VOCs) and other pollutants by combusting them at high temperatures. They help comply with environmental regulations by treating waste gases from various plant operations.

Kilns:

Kilns are fired equipment used in specific applications like cement or ceramic production. They provide controlled high-temperature environments for processes such as drying, calcination, or sintering.

Types of Fired Equipment based on the Type of Fuel

The type of fuel used by fired equipment in refineries and oil and gas plants can be classified as three major kinds:

Coal-fired equipment: This refers to equipment that burns coal as its principal fuel. Furnaces, boilers, and other devices that burn coal to generate heat or energy are examples of coal-fired machinery.

Gas-fired equipment: Natural gas or other gases are used as the fuel source in gas-fired devices. Furnaces, boilers, heaters, and other equipment designed to efficiently burn gas and produce heat for various operations are included.

Oil-fired equipment: Oil-fired equipment uses oil as a fuel, such as crude oil or refined petroleum products. In refineries and oil and gas plants, this equipment comprises furnaces, boilers, heaters, and other machines that burn oil to generate heat or energy.

To ensure safe and efficient operation inside the plant, each type of burned equipment has its own design concerns, fuel handling systems, and combustion processes.

Differences between Coal Fired, Gas Fired, and Oil Fired Equipment

The major differences between coal-fired, gas-fired, and oil-fired equipment lie in the kind of fuel they use and the combustion characteristics that are associated with each fuel. Some of their key distinctions are:

| Factors | Gas-Fired Equipment | Coal-Fired Equipment | Oil-Fired Equipment |

| Fuel Type | Natural Gas | Coal | Oil (e.g., diesel, fuel oil) |

| Combustion Efficiency | High | Moderate to Low | Moderate to High |

| Emissions | Lower | Higher | Moderate to Higher |

| Fuel Storage and Handling | Pipeline Supply | Requires coal storage, handling, and preparation | Requires oil storage, handling, and periodic deliveries |

| Ignition and Combustion Control | Automatic ignition systems, simpler control. | Simple process. | Combustion may require additional measures, control complexity can vary. |

| Maintenance and Cleaning | Moderate maintenance and cleaning are required. | Less maintenance and cleaning are required. | Moderate maintenance and cleaning required. |

| Cost | Generally stable and lower cost | Varies based on coal prices and availability | Varies based on oil prices and availability |

Environmental Considerations for Fired Equipment

In terms of environmental impact, the burning of fuels in fired equipment can have an effect on emissions. However, the industry is taking a proactive approach to resolving this issue by introducing a variety of initiatives. To improve fuel efficiency and reduce emissions, advanced combustion technologies are used. Efforts are also taken to optimise fuel usage, ensuring that it is used efficiently and effectively.

Emission control systems are used to further reduce the environmental impact. These systems aid in the capture and treatment of pollutants before they are released into the environment. Continuous research and development is conducted to identify cleaner and more sustainable solutions with the goal of reducing the carbon footprint connected with the operation of burned equipment in refineries and oil and gas plants. The industry recognizes the importance of environmental stewardship and is committed to finding innovative ways to reduce emissions and promote sustainability.