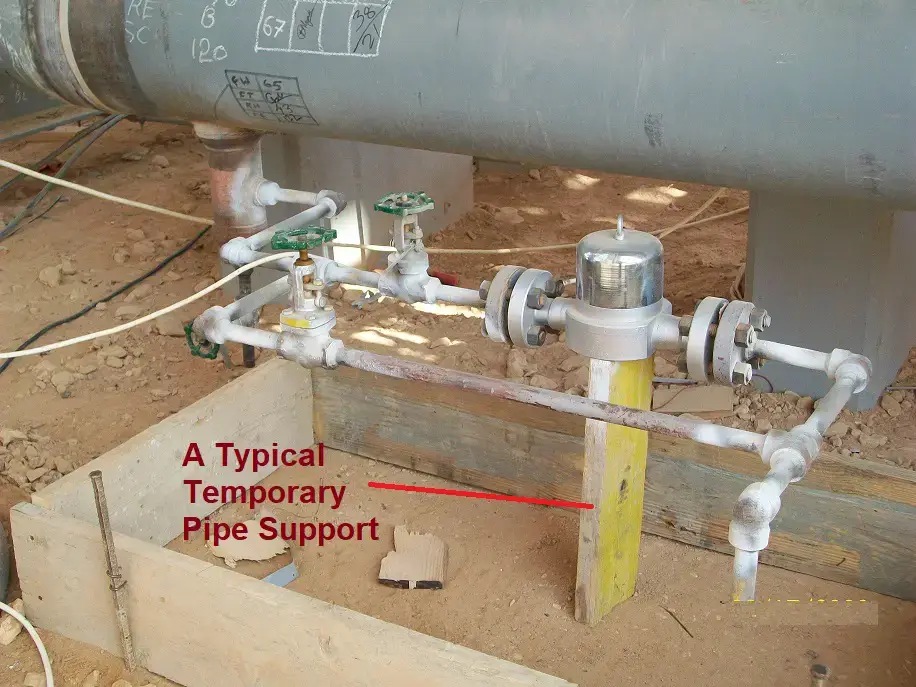

Temporary pipe support is a crucial element in construction, maintenance, and repair projects involving pipes. Its purpose is to provide the necessary support to prevent damage, deformation, or misalignment of pipes during installation or operation. These supports, which are temporary in nature, are removed once the piping or pipeline system is commissioned.

There are various types of temporary pipe supports, such as pipe clamps, hangers, stands, rollers, and saddles. These supports are designed to be adjustable, easy to install and remove, enabling their quick deployment in diverse situations.

Temporary pipe supports are typically employed when permanent supports are not yet in place or when existing supports are insufficient to bear the weight of the pipes. They can also be used to offer additional support during high-stress periods or when pipes face external forces like wind or vibration. Before positioning the piping and pipeline systems in their final location, temporary supports are often utilized to ensure proper functionality.

Requirements for Temporary Pipe Supports

Temporary pipe supports are essential requirements during the construction, maintenance, or repair of pipelines for several key reasons:

Prevent damage: Pipes are often heavy and prone to deformation or damage if not adequately supported. Temporary pipe supports offer a stable and secure platform, preventing any potential harm to the pipes during these activities.

Ensure correct alignment: Proper alignment of pipes is crucial for their optimal functioning. Temporary pipe supports aid in maintaining accurate alignment during installation, reducing the risk of leaks or other operational issues.

Allow for adjustments: The adjustability of temporary pipe supports is a vital feature. It allows workers to fine-tune the position and angle of the supports as required. This flexibility ensures proper support and alignment, facilitating seamless construction, maintenance, or repair work.

Facilitate work: By providing a stable and secure platform, temporary pipe supports enable workers to perform their tasks with enhanced safety and efficiency. The supports eliminate concerns about pipe movement or instability, allowing workers to concentrate on their work effectively.

In summary, temporary pipe supports are indispensable for the safe and efficient installation, maintenance, and repair of piping and pipeline systems. They mitigate the risk of damage, misalignment, and costly issues like leaks, ensuring successful project outcomes.

Selecting a Temporary Pipe Support

Several crucial considerations should be taken into account while selecting temporary pipe supports, including:

Pipe size and weight: The support must have the strength to withstand the weight of the pipe as well as any gases or liquids that may be flowing through it. Additionally, it must be suitable with the pipe’s thickness and diameter.

Environment at work: Take into account the type of job, the location, and the surrounding circumstances. The support should be heat-resistant, chemical-resistant, or corrosion-resistant for hazardous settings.

Adjustability: To allow variations in pipe diameter and guarantee accurate alignment, the temporary support should be flexible. Deformation or misalignment of pipes may result from rigidity.

Portability: The support should be simple to move and install, if the job site is far away or hard to get to.

Safety: To reduce the potential of accidents or injuries during installation, usage, and removal, the support should be built with safety measures.

Compatibility: Whether the pipe is composed of metal, plastic, or composite materials, be sure the temporary support is compatible with that particular type of pipe.

The right temporary pipe support can be chosen by carefully taking into account these elements in order to reduce the possibility of pipe damage, offer a safe working environment, and guarantee an efficient project completion.

Typical Examples of Temporary Pipe Supports during Design Stage

During the design phase, there are instances where temporary pipe supports are recommended. Here are a few examples:

Temporary Support during Hydrotest:

When large-diameter gas or vapor pipes undergo hydrostatic testing, temporary supports are added to transfer the loads. Permanent supports are typically not designed for the water-filled weight, leading to higher loads during testing. Temporary supports help carry part of the loads during the hydrostatic test, ensuring the loads on permanent supports remain within their design limits.

Temporary Support During Rotary Equipment Alignment:

Aligning piping flanges with rotary equipment flanges is a critical activity. Strain-sensitive rotating equipment like pumps and turbines require reduced loads during alignment. In cases where permanent supports exceed allowable loads, temporary supports are suggested by pipe stress engineers to meet alignment criteria. However, these temporary supports must be removed once alignment is complete and the equipment is ready for commissioning.

Pipe stress engineers usually mark such requirements in the piping stress isometrics and the information is passed to the construction team by a note in the isometric.

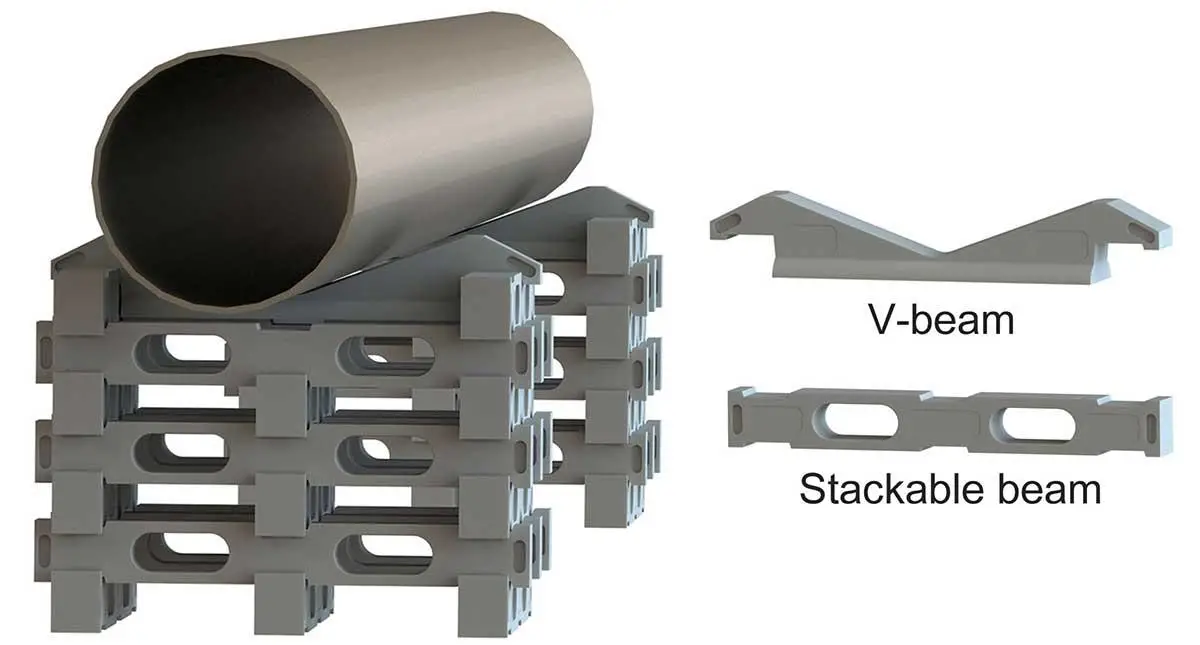

Typical Forms of Temporary Pipe Supports

Common forms of temporary pipe supports include:

- Wooden Blocks: Simple and customizable, wooden blocks are cut to size and stacked to provide support as needed.

- Adjustable Pipe Stands: These metal frames offer height and angle adjustability, accommodating pipes of various sizes and shapes.

- Pipe Clamps: Adjustable clamps attached to the pipe provide support at specific points along its length.

- Pipe Rollers: Cylindrical supports placed beneath the pipe allow for rolling movement during expansion and contraction, ideal for areas with significant movement or vibration.

- Jacks: Hydraulic or mechanical jacks lift and support pipes during maintenance, offering adjustable height and load-bearing capacity.

The selection of the appropriate temporary pipe support depends on factors such as pipe size, weight, project duration, and specific maintenance requirements. It’s important to consider these factors to ensure effective support and safety during the maintenance project.

Online Video Courses on Piping Support

To learn more about piping support design and engineering you can opt for the following video course.