A vortex breaker is a clever device used to stop swirling patterns of fluid flow, known as vortices, from forming in equipment or piping systems. These vortices can cause various issues like increased turbulence, reduced flow efficiency, and increased wear and tear on the pipes and other components.

To prevent these problems, engineers use this breaker, which is usually a small, cylindrical, triangular-shaped, or cross-shaped gadget. They install it in the vessel or pipe at the spot where the vortex is likely to appear. The device disturbs the fluid flow in such a way that it breaks up the forming vortex before it can cause trouble.

You can find this device being used in industrial cooling systems, process control systems, and oil and gas production setups. Depending on factors like fluid properties, flow rate, and pipe size, these devices can be installed inside or outside the vessel/pipe, in vertical or horizontal positions, and have various designs to suit different applications.

Vortices on Flow: Effects

There are several important reasons for avoiding the formation of vortices in fluid systems:

- Smooth Flow Obstruction: Vortices act as obstacles that disrupt the smooth flow of fluids, causing turbulence and inefficiencies in the system.

- Two-Phase Flow Issues: When vortices form, they tend to draw gases inside them, resulting in a two-phase flow. This can lead to various drawbacks and complications in the system.

- Disruption and Erosion: Vortices can change the regular flow pattern within pipes or nozzles, potentially leading to damage to the pipes and fittings.

- Pressure Reduction and Increased Pumping Force: The presence of vortices in the fluid system causes a reduction in pressure, which, in turn, requires higher pumping force to maintain the desired flow rates.

Overall, avoiding vortex formation is essential to maintain the efficiency, reliability, and longevity of fluid handling systems.

Applications of a Vortex Breaker

Vortex breakers find widespread use in various industrial and commercial applications that involve fluid flow through piping systems. Let’s take a look at some of the most common applications of vortex breakers:

- Industrial Cooling Systems:

These devices are essential in industrial cooling systems to prevent the formation of vortices in the cooling water. These vortices can hinder the system’s efficiency and cause damage to pipes and other components. - Process Control Systems:

In process control systems, vortex breakers play a crucial role in preventing vortices from forming in fluids like chemicals, oil, and gas. This ensures accurate flow measurement and control. - Oil and Gas Production:

They are utilized in the oil and gas industry to avoid vortices in production fluids. Preventing vortices helps maintain production rates, reduces equipment wear, and enhances safety. - Water Treatment Systems:

Water treatment systems benefit from this device, especially during the intake of water from rivers or lakes. By preventing vortices, the risk of debris or aquatic life getting entrained is minimized. - Fire-Protection Systems:

In fire-protection systems, vortex breakers are employed to prevent vortices in the water supply. This ensures an uninterrupted flow of water to the fire hose, increasing the effectiveness of the system. - HVAC Systems:

These are also used in HVAC systems to prevent vortices in the airflow. Doing so improves system efficiency and protects the ducts and other components from potential damage.

Using this device offers several advantages, such as improved system efficiency, reduced maintenance costs, and enhanced safety and reliability. These devices play a vital role in optimizing fluid handling systems across a wide range of industries.

Design of a Vortex Breaker

Designing a vortex breaker involves a thoughtful process to ensure its effectiveness in preventing vortices. Here are the steps typically followed in the design:

- Understand the Fluid: First, the fluid that will flow through the pipe needs to be identified, along with its properties like viscosity, density, and flow rate. These characteristics play a significant role in the design process.

- Identify Vortex Formation Point: Determine the location where vortices are likely to form along with the specific pipe size and configuration at that point. This helps in placing the breaker optimally.

- Material Selection: Choosing the right materials for this device is crucial. Consider factors such as corrosion resistance, pressure and temperature ratings, and compatibility with the fluid being handled.

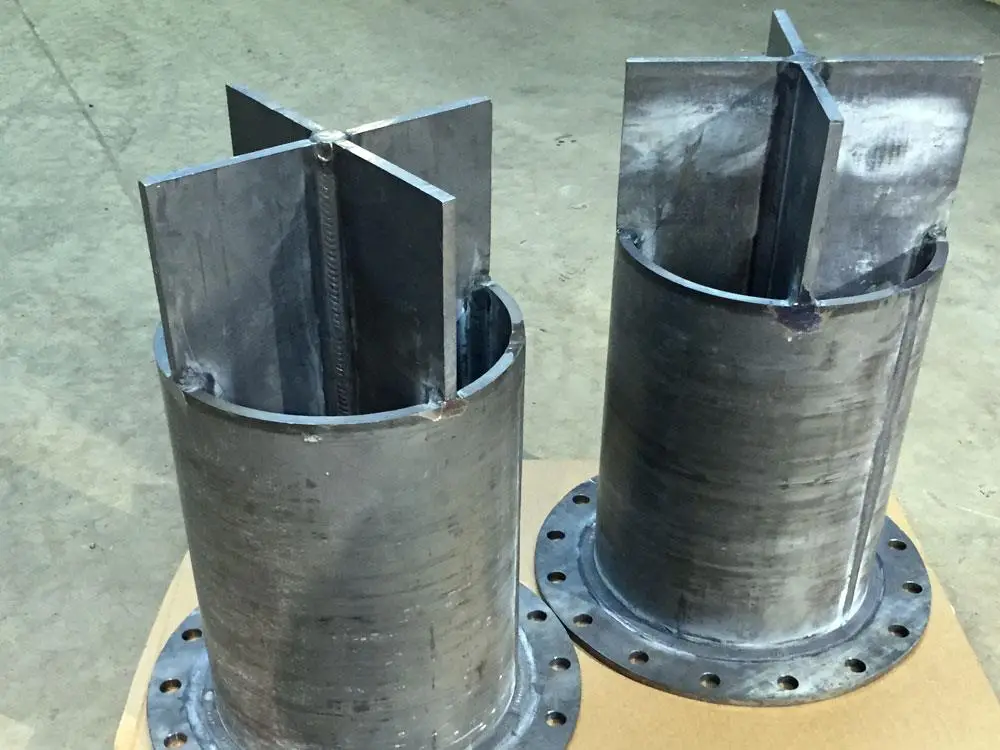

- Size and Shape Considerations: Based on the fluid properties, pipe size, and flow rate, calculate the appropriate size and shape of the breaker. Common shapes include cylindrical or triangular designs.

- Layout and Drawing: Create a detailed layout and drawing of the vortex breaker, specifying its location, size, and shape. This serves as a blueprint for implementation.

- Safety and Maintenance: Ensure that safety and maintenance aspects are taken into account during the design process. The device should be designed for easy access and maintenance.

- Flow Simulation and Analysis: Conduct flow simulations, such as computational fluid dynamics (CFD) analysis, to verify the design and identify any potential issues that may affect performance.

- Professional Consultation: Consult with relevant professionals, like engineers or fluid dynamics experts, to gain valuable insights and expertise. Also, adhere to industry standards and codes for compliance.

Remember, each vortex breaker design is unique to its application, considering factors like fluid properties, pipe size, and configuration. Taking these aspects into consideration ensures an effective and well-suited vortex breaker design for the intended use.

Working of the Device

A vortex breaker is a clever device that does quite an important job in a piping system. As discussed earlier, when fluid flows through bends or restrictions like elbows or valves in the pipe, it can create swirling patterns called vortices. And these vortices can be a real headache, causing all sorts of issues like turbulence, reduced flow efficiency, and even wearing down the pipes and other components over time.

This device disrupts the flow of fluid, preventing these vortices from forming. When the fluid encounters the vortex breaker, it’s directed to flow around it, and this creates a separation in the flow that breaks up the vortex before it even gets a chance to form.

Further, the vortex breaker not only prevents vortex formation but also helps improve the overall flow efficiency. That means reduced pressure drop and better performance for the whole system.

Now, keep in mind that the design and placement of the breaker are critical in order to achieve desired results. You have to consider things like the fluid properties, how fast it’s flowing, and the size of the pipes when designing the vortex breaker to get the best results. So, it’s all about finding the right fit for your specific system to keep those vortices in check!

Types of Vortex Breakers

There are several types of vortex breakers, each designed with unique features to suit different applications. Let’s take a look at some of the most common types:

- Cylindrical Vortex Breaker: This type is a small cylindrical device placed inside the pipe at a perpendicular angle to the fluid flow. It helps prevent vortices from forming and is commonly used in industrial cooling systems and process control setups.

- Triangular Vortex Breaker: Similar to the cylindrical one, but with a triangular shape. It’s also placed perpendicular to the fluid flow and finds applications in oil and gas production and water treatment systems.

- Plate Vortex Breaker (Disc or Cross Type): A flat plate installed in the pipe, either vertically or horizontally, to disrupt vortex formation. This type is used in HVAC systems, fire-protection systems, and process control applications.

- Spike Vortex Breaker: This small device features a spike-like shape and is typically installed vertically. It is used in industrial cooling systems and process control setups.

- Spiral Vortex Breaker: With a spiral shape, this device is installed vertically and commonly used in oil and gas production and process control systems.

Remember, when choosing this particular device, it’s crucial to consider the specific application, the fluid properties, and the pipe size and configuration. Consulting with experts and following industry standards and codes ensures the device’s effectiveness and proper integration into the system.

Manufacturers of Vortex Breakers

There are several well-known manufacturers of vortex breakers, each offering a wide range of products for different industries and applications. Some reputable manufacturers include:

- Spirax Sarco: They are known for their expertise in flow control products, including these breakers, catering to various industries.

- Fluid Components International (FCI): FCI is a leading manufacturer of this device and other flow measurement and control solutions.

- Vortab: Vortab specializes in this device and flow control products, serving diverse industries.

- Vortex Flow Control: They are recognized for manufacturing high-quality vortex breakers and flow control devices.

- Pro Flow Dynamics: Pro Flow Dynamics is known for its vortex breakers and other flow control solutions.

- Badger Meter: Badger Meter is a reputable manufacturer offering vortex breakers and other flow measurement and control products.

- Flow-Tech Industries: This industry provides a range of vortex breakers and flow control solutions for various applications.

It’s necessary to conduct thorough research on different manufacturers and their products before making a purchase. Consider factors such as the suitability of the vortex breaker for your specific application and the manufacturer’s reputation for delivering quality and reliable products. A well-informed decision will ensure that you get the right vortex breaker for your needs.

Vortex Breaker in Tanks

A vortex breaker in tanks serves an important role in preventing swirling patterns of fluid flow, known as vortices, from causing trouble inside the tank. These vortices can occur when fluid is pumped into or out of the tank or when the fluid level changes.

These swirling patterns can lead to problems like turbulence, reduced flow efficiency, and increased wear and tear on the tank and its components. To avoid such issues, the vortex breaker is placed either at the tank’s inlet or outlet or at the fluid’s surface inside the tank.

Vortex breakers in tanks come in different types and designs depending on the specific application and fluid properties. Here are some common types:

- Roof-Mounted Vortex Breaker: This device is installed on the tank’s roof to prevent vortices from forming at the fluid’s surface. It’s typically used in oil and gas storage tanks.

- Surface-Mounted Vortex Breaker: Installed at the fluid’s surface, this device prevents vortex formation. It finds applications in industrial cooling systems and process control setups.

- Inlet-Mounted Vortex Breaker: Placed at the tank’s inlet, this device prevents vortices when fluid is being pumped into the tank. It’s commonly used in water treatment systems and fire-protection setups.

- Outlet-Mounted Vortex Breaker: This type is installed at the tank’s outlet to prevent vortices when fluid is being pumped out. It’s often used in industrial cooling systems and process control setups.

Vortex breakers in tanks are designed to enhance system efficiency, reduce maintenance costs, and improve safety and reliability. When designing a vortex breaker for a tank, it’s crucial to consider factors like fluid properties, flow rate, and the tank’s size and configuration. Taking these aspects into account ensures the vortex breaker functions effectively and contributes to the smooth operation of the tank system.

Vortex Breaker in Pump Suction

A vortex breaker in pump suction is a nifty device designed to stop vortices from forming in the suction line of a pump. These vortices can be a real headache, causing issues like reduced flow efficiency, cavitation, and extra wear on the pump and its parts.

The vortex breaker itself is a small gadget, often cylindrical or triangular in shape, installed near the pump in the suction line. Its purpose is to disrupt the fluid flow in such a way that it breaks up any forming vortex before it becomes a problem. The shape and position of the vortex breaker in the pipe create this disruption.

By using a vortex breaker in pump suction, you can enhance the system’s efficiency, performance, and reliability while reducing maintenance costs. But keep in mind, when designing the vortex breaker for your pump suction, consider factors like the fluid properties, flow rate, and the size and configuration of the suction pipe to get the best results.