Vibration measurement encompasses the systematic quantification of oscillatory motion’s magnitude, frequency, and direction within physical systems. This crucial process relies on various sensors, notably accelerometers, to gauge vibrations in objects or structures.

Industries spanning automotive, aerospace, and civil engineering heavily rely on vibration measurements due to the potential damage that excessive vibrations can inflict upon machinery and structures over time. By precisely measuring vibrations, engineers and technicians can swiftly identify underlying issues and implement proactive measures to prevent further damage or failure.

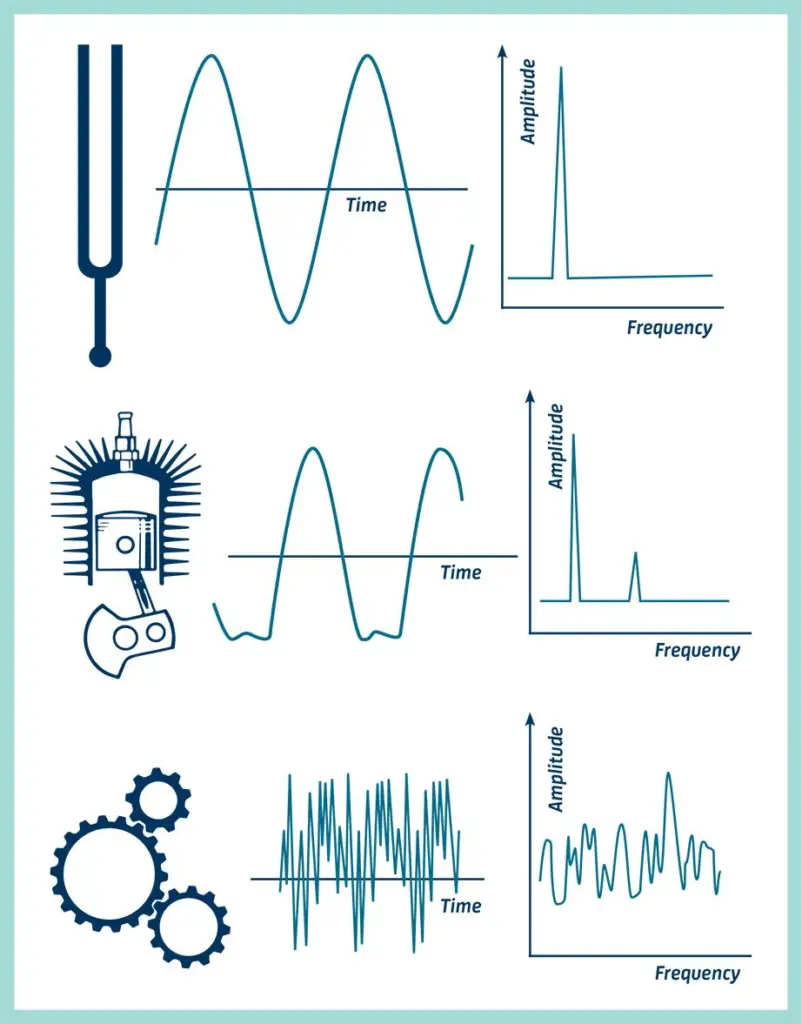

In-depth analysis of vibration measurements involves utilizing tools such as signal processing and spectral analysis. These techniques aid in uncovering the root causes of vibrations and devising effective solutions to mitigate them.

Essential Requirements for Accurate Vibration Measurement

The importance of vibration measurement arises from several significant reasons:

- Preventing damage: Excessive vibrations can gradually lead to the deterioration and eventual failure of machinery and structures. By conducting vibration measurements, engineers and technicians can detect early signs of potential issues and promptly implement corrective measures, thereby preventing further damage or costly breakdowns.

- Improving performance: Vibration measurements offer valuable insights into the behavior of systems. By pinpointing the sources of unwanted vibrations, engineers can make design modifications or adjustments to optimize performance. Reducing or eliminating detrimental vibrations can enhance efficiency, productivity, and overall system performance.

- Ensuring safety: Vibrations can pose a significant risk to human safety. High-intensity vibrations may cause discomfort, fatigue, or even injury to individuals working in close proximity to vibrating equipment or structures. By measuring vibrations, engineers and technicians can ensure that vibration levels are within safe limits, ensuring the well-being of personnel.

- Regulatory compliance: Certain industries have specific regulatory standards and requirements regarding vibration levels in equipment and structures. Compliance with these regulations is essential to avoid legal ramifications and financial penalties. By conducting vibration measurements, organizations can ensure adherence to regulatory guidelines, maintaining compliance and avoiding potential consequences.

In summary, vibration measurement plays a vital role in various industries, facilitating the prevention of damage, optimization of performance, assurance of safety, and compliance with regulatory standards. By proactively monitoring vibrations, engineers and technicians can safeguard the reliable and efficient operation of machinery and structures.

Vibration Measurement Techniques: Methods and Instruments

Vibration measurement encompasses a range of techniques, with accelerometers being the most commonly used sensors. These devices quantify the acceleration of a vibrating object, allowing for the calculation of vibration amplitude and frequency.

Accelerometers are typically affixed to the object’s surface using adhesive or mounting screws. They can be configured to measure vibration in one, two, or three dimensions, depending on the specific requirements.

Once attached, the accelerometer generates an electrical signal proportional to the object’s acceleration. This signal is then amplified, filtered to eliminate noise or interference, and recorded or displayed on a computer or data acquisition system.

Vibration measurements are analyzed using various tools and techniques, including time-domain analysis, frequency-domain analysis, and statistical analysis. These methods aid engineers and technicians in understanding vibration characteristics such as frequency, amplitude, and direction, enabling the development of appropriate solutions.

The measured vibration data serves multiple purposes, depending on the application and parameters being measured:

- Maintenance and monitoring: Vibration data enables the continuous monitoring of machinery and equipment, facilitating the detection of changes that may indicate potential failures or performance degradation. This proactive approach minimizes downtime, enhances equipment reliability, and optimizes maintenance schedules.

- Design and testing: Vibration data plays a crucial role in the design and testing of mechanical systems and structures, ensuring their safety, durability, and reliability under different environmental and load conditions.

- Performance optimization: Vibration data aids in optimizing the performance of machinery and equipment by identifying areas with high vibration levels. Implementing appropriate changes to reduce or eliminate vibration sources leads to improved performance and operational efficiency.

- Quality control: Vibration data contributes to quality control processes, ensuring that products meet specified standards and are free from vibration-related defects or issues.

- Research and development: Vibration data is invaluable in research and development projects, providing insights into the behavior and performance of mechanical systems and structures across various conditions.

In summary, a comprehensive understanding of vibration measurement techniques, coupled with accurate data analysis, empowers professionals to assess and address vibration-related challenges in diverse fields.

Unit of Vibration Measurement

The vibration unit of measurement is determined by the parameter under consideration. Acceleration is the most generally used unit, and it is typically measured in metres per second squared (m/s2) or g-forces (g), where 1 g = 9.81 m/s2.

Multiple units are used to quantify various elements of vibration:

Velocity: The rate of change of displacement is indicated by velocity, which is measured in metres per second (m/s) or inches per second (in/s).

Displacement: Measured in metres (m) or inches (in), displacement is the amount of movement from a reference position.

Frequency: Frequency is measured in Hertz (Hz) or cycles per second (CPS) and represents the number of oscillations or cycles per unit of time.

When selecting the appropriate unit of vibration measurement, it is crucial to consider the specific application and the parameters being evaluated. Engineers and technicians choose the unit based on the requirements and standards relevant to their particular field of work.

Quantifying Vibration

Vibration can be quantified using various methods, depending on the specific application and parameters being measured. Here are some commonly used techniques:

- Amplitude: Amplitude refers to the maximum displacement, velocity, or acceleration of a vibrating object from its equilibrium position. It is measured in units such as meters (for displacement), meters per second (for velocity), or meters per second squared (for acceleration).

- Frequency: Frequency represents the number of oscillations or cycles per unit of time. It is typically measured in units like Hertz (Hz) or cycles per second (CPS).

- Power Spectral Density (PSD): PSD is a measure of energy distribution across different frequencies in a vibration signal. It is expressed in units such as g^2/Hz, where g represents the acceleration due to gravity.

- Root Mean Square (RMS): RMS is an average energy measure of a vibration signal over time. It is commonly expressed in units like g (for acceleration) or mm/s (for velocity).

- Crest Factor: The crest factor indicates the ratio of the peak amplitude of a vibration signal to its RMS value. It is often utilized to assess the severity of high-frequency vibration signals.

- Kurtosis: Kurtosis measures the peakedness of a vibration signal. It is particularly useful for assessing the presence of high-frequency or impulsive vibration signals.

These techniques enable engineers and technicians to quantify and analyze vibrations, providing valuable insights for diagnostics, monitoring, and maintenance purposes in various industries.

Vibration Measurement Instruments

There are several types of instruments commonly used to measure vibration, each with its own limitations and considerations for selection. Here are some of the most frequently utilized instruments:

- Accelerometers: Accelerometers are widely used for vibration measurement. They quantify the acceleration of a vibrating object, enabling the calculation of vibration amplitude and frequency.

- Velometers: Velometers measure the velocity of a vibrating object. They are typically suitable for measuring low-frequency vibrations.

- Displacement probes: Displacement probes gauge the displacement of a vibrating object. They are often employed for measuring high-frequency vibrations.

- Proximity probes: Proximity probes assess the distance between a vibrating object and a stationary surface. They are commonly used in monitoring the vibrations of rotating machinery.

- Laser vibrometers: Laser vibrometers employ laser beams to measure vibrations without direct contact with the object. They are particularly useful for delicate or hard-to-reach objects.

- Tachometers: Tachometers measure the rotational speed of a shaft or motor. They are frequently utilized for assessing the vibration of rotating machinery.

- Spectrum analyzers: Spectrum analyzers are instrumental in analyzing the frequency content of a vibration signal. They aid in identifying the sources of unwanted vibrations and developing appropriate solutions.

When selecting a vibration measuring tool, it is crucial to consider factors such as the frequency range of interest, measurement accuracy, portability, and specific requirements of the application at hand.

Applications of Vibration Measurement

Vibration measurement finds extensive applications across diverse industries. Here are some notable examples:

- Industrial machinery: Vibration measurement plays a vital role in the maintenance and monitoring of industrial machinery. It helps detect changes in vibration that may signify equipment failure or performance degradation, enabling timely interventions to minimize downtime, enhance reliability, and optimize maintenance schedules.

- Aerospace: Vibration measurement is critical in the aerospace industry. It is employed to monitor the structural integrity of aircraft components and ensure that vibrations remain within safe limits during operation, safeguarding passenger safety and enhancing overall aircraft performance.

- Automotive: Vibration measurement is integral to the design and testing of automobiles. It is used to evaluate ride comfort, detect potential issues in suspension or steering systems, and optimize vehicle performance for a smooth and reliable driving experience.

- Civil engineering: Vibration measurement is indispensable in civil engineering, particularly in the design and assessment of structures like bridges and buildings. It helps ensure structural safety and stability under various environmental and load conditions, mitigating risks and ensuring long-term durability.

- Medical devices: Vibration measurement is employed in the development and testing of medical devices to ensure they operate within safe limits. It helps verify the performance and reliability of surgical instruments, implants, and other medical equipment, ensuring patient safety and optimal functionality.

- Consumer electronics: Vibration measurement is utilized in the design and testing of consumer electronics. It ensures that devices like smartphones, laptops, and appliances can withstand vibrations encountered during usage, enhancing their durability, performance, and user experience.

- Oil and gas industries: Vibration measurement is applied in the oil and gas sector to monitor the health and integrity of equipment, such as pumps, turbines, and compressors. By detecting abnormal vibrations, potential failures can be identified and preventive maintenance measures can be implemented, minimizing costly downtime and ensuring operational efficiency.

These examples highlight the broad range of applications where vibration measurement is essential for ensuring safety, reliability, and optimal performance across various industries.

Industry Standards for Oil and Gas Vibration Measurement

In the oil and gas industry, there are several industry standards that govern vibration measurement and evaluation. These standards provide guidelines for ensuring the safe and reliable operation of equipment. Here are some notable industry standards:

- API 618/API 674: These standards specifically focus on reciprocating compressors and pumps used in the petroleum, petrochemical, and natural gas industries. They specify vibration limits and criteria to ensure the proper functioning of these critical equipment.

- ISO 10816: This standard offers comprehensive guidelines for the measurement and evaluation of vibration in industrial machinery. It provides vibration limits for various types of machines, including pumps, fans, and compressors, helping to ensure their safe and reliable operation.

- ASME PTC 19.3: This standard is specifically tailored for measuring vibration in piping systems. It outlines procedures for measuring vibration levels, identifying vibration sources, and evaluating vibration severity. It helps to detect potential issues in piping systems and prevent failures.

- ANSI/HI 9.6.4: This standard focuses on centrifugal pumps. It provides guidelines for measuring and evaluating vibration in these pumps, specifying allowable vibration levels for different pump types and operating conditions. It assists in maintaining reliable pump performance and preventing failures.

- NEMA MG 1-2018: This standard is concerned with vibration measurement in electric motors. It provides guidelines for evaluating vibration levels in motors, specifying allowable vibration limits for different motor types and operating conditions. It helps ensure motor reliability and performance.

Additionally, industry organizations such as the Energy Institute also offer guidelines and best practices for vibration measurement in the oil and gas industry.

These industry standards serve as essential references, guiding professionals in accurately measuring, assessing, and managing vibrations in equipment, ensuring their safe and reliable operation in the oil and gas sector.

Vibration Meter

A vibration meter is a portable device designed to measure the vibration levels of mechanical systems or structures. It consists of essential components such as a sensor, display unit, and software for data analysis.

The sensor is typically an accelerometer, which is attached to the surface of the object under measurement. It captures the acceleration of the object, allowing for the calculation of vibration amplitude and frequency. Some vibration meters may incorporate additional sensors, such as velocity sensors or displacement probes, to provide more comprehensive information about the vibration characteristics.

The display unit of a vibration meter presents real-time vibration measurements, enabling operators to monitor the vibration levels and make necessary adjustments if required. Certain vibration meters may also offer advanced features, including the capability to store and analyze vibration data over time or connect to a computer or data acquisition system for in-depth analysis.

Vibration meters find extensive use in the maintenance and monitoring of industrial machinery, serving as valuable tools to identify any variations in vibration that might indicate equipment failure or performance deterioration. Moreover, they are employed across diverse industries like aerospace, automotive, and civil engineering to measure and analyze vibrations in machinery and structures.

These portable devices enhance the ability to detect and address vibration-related issues promptly, ensuring the optimal performance, safety, and longevity of mechanical systems and structures.