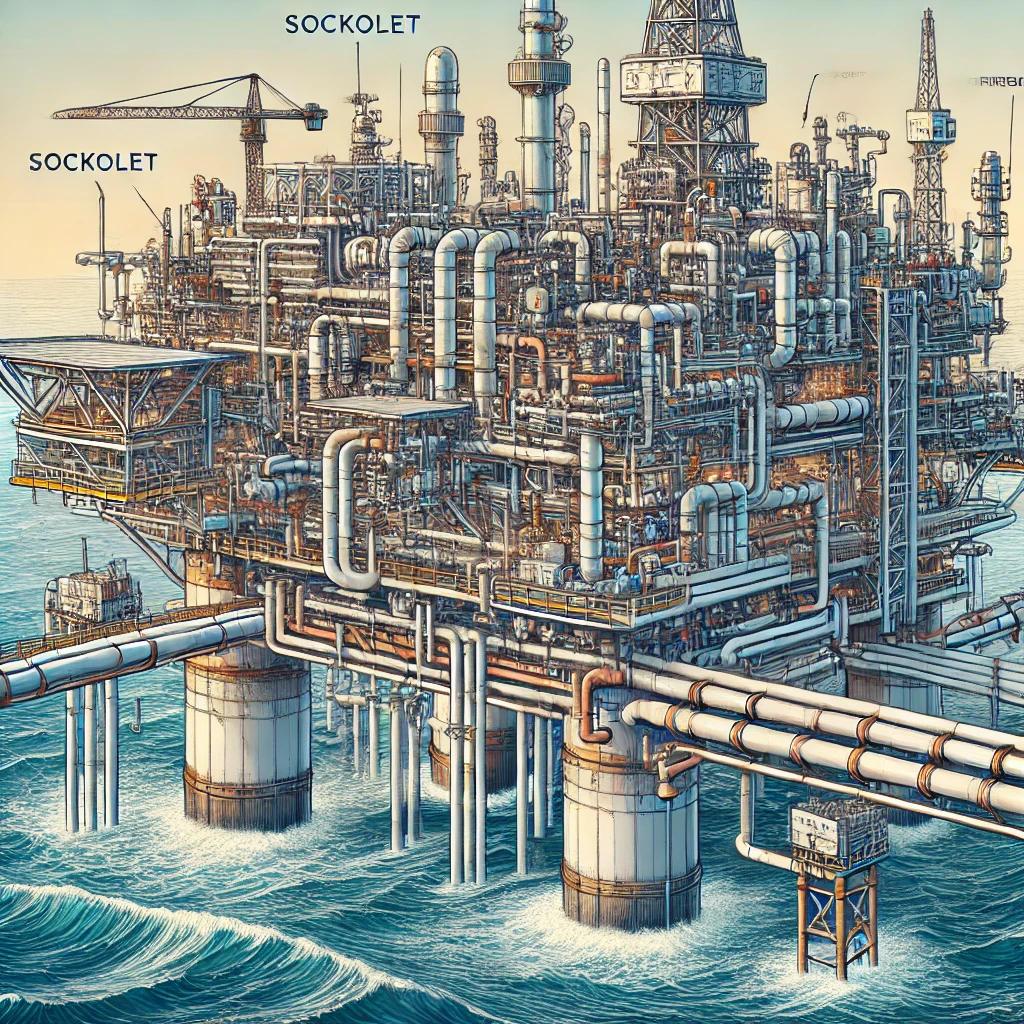

In the vast and complex world of ocean engineering, the term “sockolet” may not immediately come to mind. However, this small yet crucial fitting plays a significant role in various marine applications, contributing to the safety, efficiency, and integrity of offshore structures. In this blog, we will explore the concept, its applications in ocean engineering, and how it supports the dynamic needs of the industry.

What is a Sockolet?

A sockolet is a type of branch connection fitting used in piping systems. It is designed to provide a smooth transition from a larger pipe to a smaller one, ensuring structural integrity and fluid flow efficiency. It has a socket end that fits over the branch pipe, and it is welded to both the branch and the main pipe. This fitting is known for its robustness and reliability, making it a preferred choice in high-pressure and high-stress environments.

Sockolet in Piping Systems

In any industrial setting, the integrity of piping systems is paramount. This is especially true in ocean engineering, where the harsh marine environment can pose significant challenges. Sockolets are commonly used to create branch connections in pipelines, allowing for the distribution of fluids and gases with minimal risk of leaks or failures. Their ability to withstand high pressure and corrosion makes them ideal for use in offshore oil and gas platforms, undersea pipelines, and other marine structures.

The Role of Sockolet in Ocean Engineering

Ocean engineering encompasses a wide range of activities, from the design and construction of offshore platforms to the development of undersea cables and pipelines. The use in these applications is crucial for several reasons:

- Structural Integrity: Offshore structures, such as oil rigs and wind turbines, rely heavily on robust piping systems to transport fluids and gases. This ensures a secure and leak-free connection, maintaining the structural integrity of the entire system.

- Corrosion Resistance: The marine environment is notoriously harsh, with saltwater posing a constant threat of corrosion. Sockolets, often made from corrosion-resistant materials such as stainless steel or alloy steel, provide an added layer of protection against this challenge.

- Ease of Installation: The design allows for easy installation and maintenance, reducing downtime and costs associated with repairs and replacements. This is particularly important in ocean engineering, where accessibility can be limited.

Applications of Sockolet in Ocean Engineering

1. Offshore Oil and Gas Platforms

One of the most critical applications in ocean engineering is in offshore oil and gas platforms. These structures require extensive piping networks to transport crude oil, natural gas, and other fluids from the seabed to the surface. Sockolets are used to create branch connections in these pipelines, ensuring efficient flow and minimal risk of leaks. Their ability to withstand high pressure and corrosive environments makes them indispensable in this context.

2. Undersea Pipelines

Undersea pipelines are used to transport oil, gas, and other substances across vast distances under the ocean. The integrity of these pipelines is paramount, as even a small leak can have catastrophic environmental consequences. Sockolets provide a reliable solution for creating branch connections in these pipelines, ensuring that they remain secure and leak-free.

3. Marine Renewable Energy Systems

The rise of renewable energy has led to the development of offshore wind farms and other marine energy systems. These structures require robust piping systems to transport fluids, such as hydraulic fluids used in the operation of wind turbines. Sockolets play a crucial role in ensuring the reliability and efficiency of these systems, contributing to the overall success of renewable energy projects.

4. Subsea Processing Systems

Subsea processing systems are used to process oil and gas directly on the seabed, reducing the need for extensive surface infrastructure. These systems require complex piping networks to transport fluids between different processing units. Sockolets are used to create secure branch connections in these networks, ensuring that the entire system operates smoothly and efficiently.

Material Considerations for Sockolet in Ocean Engineering

The choice of material is critical, especially in the harsh marine environment. Common materials used for sockolets in ocean engineering include:

- Stainless Steel: Known for its excellent corrosion resistance, stainless steel is a popular choice for sockolets used in marine applications. It can withstand the harsh saltwater environment, ensuring long-term durability.

- Alloy Steel: Alloy steel offer a balance between strength and corrosion resistance. They are often used in high-pressure applications where additional strength is required.

- Duplex Stainless Steel: Duplex stainless steel combines the best properties of austenitic and ferritic stainless steels, offering superior strength and corrosion resistance. This makes it an ideal choice for sockolets used in the most demanding ocean engineering applications.

Case Studies: Real-World Applications

To fully appreciate the significance of sockolets in ocean engineering, it’s essential to examine some real-world case studies. These examples highlight the practical applications and benefits of using sockolets in various marine environments and projects.

Case Study 1: Offshore Oil and Gas Platform in the North Sea

Project Overview: An offshore oil and gas platform located in the North Sea, known for its harsh weather conditions and rough seas, required a robust piping network to transport crude oil and natural gas from subsea wells to the platform for processing.

Challenge: The primary challenge was ensuring the integrity of the piping connections under high-pressure conditions and minimizing the risk of corrosion due to the saline environment.

Solution: Engineers chose to use stainless steel sockolets for all branch connections in the piping network. The sockolets provided secure and leak-free connections, capable of withstanding high pressures. Their corrosion-resistant properties also ensured long-term durability.

Outcome: The use of sockolets significantly reduced maintenance costs and downtime. The platform operated efficiently, with no reported leaks or failures in the piping network, even in the harsh conditions of the North Sea.

Case Study 2: Undersea Pipeline Project in the Gulf of Mexico

Project Overview: A major undersea pipeline project in the Gulf of Mexico aimed to transport natural gas from offshore wells to onshore processing facilities. The pipeline had to traverse a variety of seabed conditions and depths.

Challenge: Creating secure branch connections along the lengthy pipeline while ensuring minimal environmental impact and maintaining pipeline integrity over long distances.

Solution: Alloy steel sockolets were used for branch connections throughout the pipeline. The high strength of the alloy steel ensured the connections could withstand the varying pressures and stresses encountered along the pipeline route. Additionally, the use of advanced welding techniques provided added strength and security.

Outcome: The project was completed successfully, with the pipeline operating smoothly and efficiently. The use of sockolets contributed to the pipeline’s reliability, and there were no significant environmental incidents related to leaks or failures.

Case Study 3: Offshore Wind Farm in the North Atlantic

Project Overview: An offshore wind farm located in the North Atlantic aimed to harness wind energy to generate electricity. The project included multiple wind turbines, each requiring a network of pipes to transport hydraulic fluids necessary for turbine operation.

Challenge: Ensuring the reliability and efficiency of the piping network in a highly corrosive marine environment and under the mechanical stresses caused by the movement of the turbines.

Solution: Duplex stainless steel sockolets were chosen for the branch connections in the piping network. The duplex stainless steel provided excellent corrosion resistance and mechanical strength, making it ideal for the harsh conditions of the North Atlantic.

Outcome: The wind farm achieved high operational efficiency with minimal maintenance requirements. The durability of the sockolets contributed to the overall reliability of the system, allowing the wind farm to consistently generate electricity.

Case Study 4: Subsea Processing Facility in the South China Sea

Project Overview: A subsea processing facility in the South China Sea was designed to process natural gas directly on the seabed, reducing the need for extensive surface infrastructure.

Challenge: Creating a complex network of pipes and connections capable of withstanding the high pressures and corrosive environment of the deep sea.

Solution: Engineers selected duplex stainless steel sockolets for the branch connections within the subsea processing system. The material’s strength and corrosion resistance were critical in ensuring the system’s long-term viability.

Outcome: The subsea processing facility operated efficiently, with the sockolets performing reliably under the challenging conditions. The project demonstrated the feasibility of subsea processing, paving the way for similar projects in the future.

Case Study 5: Pipeline Rehabilitation in the Mediterranean Sea

Project Overview: An existing undersea pipeline in the Mediterranean Sea required rehabilitation to address leaks and corrosion issues. The project aimed to extend the pipeline’s operational life without significant downtime.

Challenge: Ensuring secure and durable branch connections during the rehabilitation process, while minimizing disruption to the pipeline’s operation.

Solution: Stainless steel sockolets were used for the replacement and repair of branch connections. The sockolets’ ease of installation and corrosion resistance were critical factors in their selection.

Outcome: The rehabilitation project was completed successfully, with the pipeline returning to full operation with improved reliability. The use of sockolets contributed to the extended operational life of the pipeline, reducing the need for future repairs.

The Future of Sockolet in Ocean Engineering

As the field of ocean engineering continues to evolve, the demand for reliable and robust piping solutions will only increase. The sockolet, with its proven track record of performance and reliability, will remain a critical component in the industry. Advances in materials science and manufacturing techniques will likely lead to the development of even more durable and efficient, further enhancing their role in ocean engineering.

Innovations in Sockolet Design

Innovations in design are focused on improving performance and reducing costs. For example, the development of advanced welding techniques can enhance the strength and integrity of sockolet connections. Additionally, the use of computer-aided design (CAD) and simulation tools can optimize the design, ensuring that they meet the specific requirements of each application.

In conclusion, the sockolet is a small but essential fitting that plays a significant role in the field of ocean engineering. Its ability to create secure and reliable branch connections in piping systems makes it indispensable in a variety of marine applications. From offshore oil and gas platforms to undersea pipelines and renewable energy systems, the sockolet ensures the integrity and efficiency of critical infrastructure.

As ocean engineering continues to advance, the importance of reliable and robust piping solutions will only grow. The sockolet, with its proven track record and ongoing innovations, will remain a cornerstone of this dynamic and challenging field. By understanding the role of sockolet and its applications, we can appreciate the intricate engineering that goes into maintaining the safety and functionality of our marine environments.

In the ever-evolving landscape of ocean engineering, the sockolet stands as a testament to the importance of small but vital components in ensuring the success of large-scale projects. Its contributions to the industry underscore the value of precision engineering and the ongoing quest for excellence in the face of formidable challenges.