Efficient information management is vital for smooth industrial processes and optimal productivity. In various industries, such as oil and gas, process datasheets serve as essential tools for effective communication, equipment procurement, and decision-making. This article explores the significance of process datasheets, their structure, and how they streamline operations across different sectors.

During the detailed design phase of a project, process datasheets are crucial deliverables. They quantify and define each piece of equipment, allowing for accurate equipment procurement. Once the Piping and Instrumentation Diagram (P&ID) is prepared by the Process team, the next step is to create process datasheets for each equipment component. These datasheets can then be shared with suppliers or vendors to obtain pricing and facilitate the procurement process.

Process Data Sheet: An Essential Tool for Efficient Industrial Operations

A Process Datasheet, also referred to as a Design Datasheet or Process Equipment Datasheet, is a document that summarizes the performance and technical characteristics of equipment or systems within an industrial process. It serves as a crucial tool during the detailed design phase, providing the necessary information to specify and procure the required equipment.

These design datasheets consolidate all the fundamental technical requirements for specifying the equipment. They outline the technical specifications, operational parameters, and other essential details necessary for accurate equipment selection and design.

Further, they play a vital role in facilitating effective collaboration between engineering and procurement teams. By providing a standardized format and a consolidated source of information, process datasheets ensure that all stakeholders have a clear understanding of the equipment requirements. This helps minimize the risk of miscommunication and supports efficient decision-making throughout the procurement process.

Overall, process datasheets streamline the process of designing, specifying, and procuring equipment for industrial processes. They serve as a valuable reference document, ensuring that the technical specifications and operational requirements are accurately captured, leading to efficient and successful project execution.

Understanding Process Datasheets

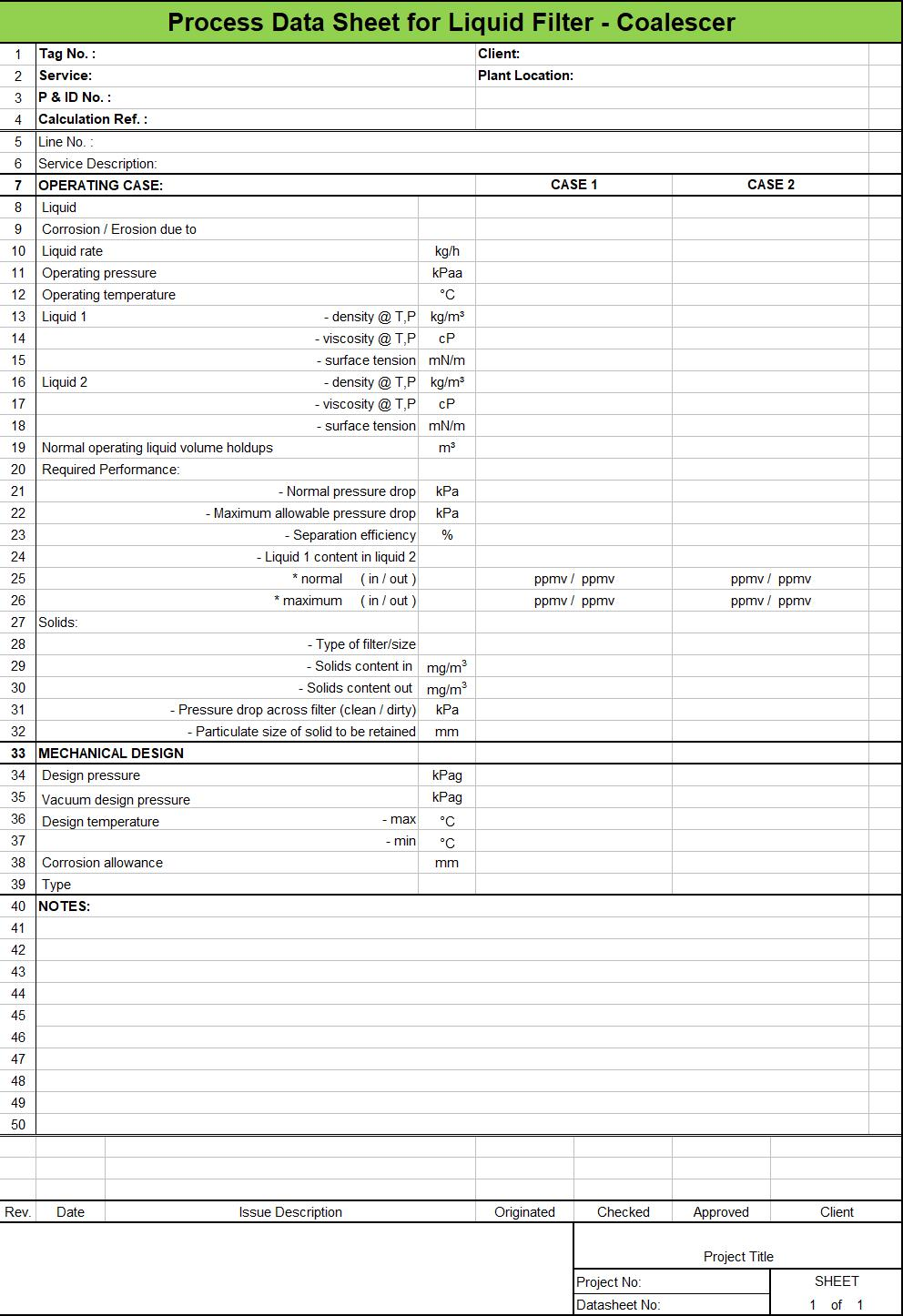

Structure and Components of Process Datasheets

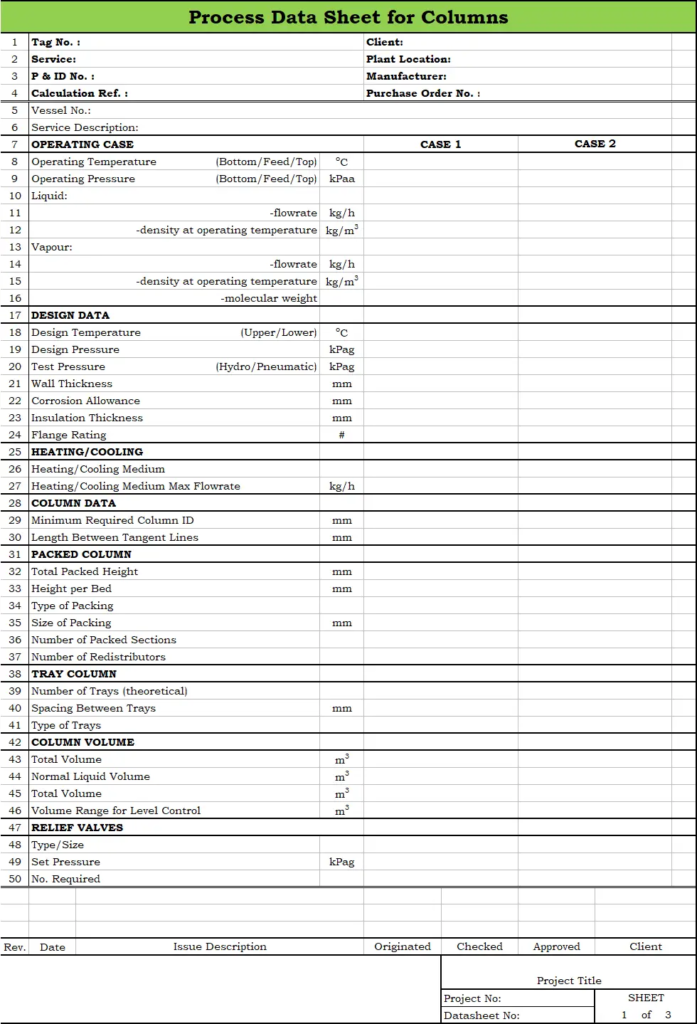

Design datasheets in the oil and gas industries typically follow a structured format with various sections. Let’s explore the key components:

General Information:

This section provides an overview of the equipment, including its name, tag number, and a brief description of its function. It helps stakeholders understand the equipment’s role within the larger process context.

Process Parameters:

Critical process parameters such as temperature, pressure, flow rates, and other relevant variables are documented here. These parameters assist in assessing the equipment’s suitability for the specific process requirements.

Design and Construction:

This section outlines the design specifications, construction materials, dimensions, and installation requirements for the equipment. It ensures that the procurement team can select the appropriate equipment that aligns with process needs and meets industry standards.

Performance and Efficiency:

Process datasheets highlight the equipment’s performance characteristics and efficiency metrics. This information helps evaluate whether the equipment can meet production targets, energy efficiency goals, and overall process optimization.

Additionally, process datasheets include information such as:

- Overall size and geometry of the equipment, including diameter and length.

- Identification of nozzle and tie-in point connections.

- Material of construction, including specifications for corrosion allowance, cladding, or lining requirements.

- Full range of operating conditions, including design pressure, operating temperature, fluid type, and test pressure.

- Specific notes and remarks that provide additional details or instructions.

In some cases, a simple diagram may be included in the process datasheet to visually represent the technical specifications. Mechanical datasheets for equipment can also be prepared using the process datasheets as a reference.

Overall, these datasheets serve as important communication tools between vendors, suppliers, and clients. They ensure that all stakeholders have a clear understanding of the equipment’s technical specifications, facilitating effective procurement and successful project execution.

The Significance and Benefits of Process Datasheets in Industrial Operations

Across industrial operations, these datasheets offer several significant benefits :

Standardized Communication:

Process datasheets provide a standardized format for conveying technical information, ensuring clear and effective communication among engineering, procurement, and maintenance teams. This promotes better understanding, reduces misunderstandings, and facilitates faster decision-making.

Streamlined Procurement:

By specifying equipment requirements and technical details, process datasheets streamline the procurement process. Procurement teams can refer to these datasheets to identify suitable vendors and select equipment that aligns with the project’s needs, minimizing the risk of purchasing incompatible or unsuitable equipment.

Enhanced Safety and Compliance:

Process datasheets include essential safety considerations, such as hazardous area classifications and required safety features. Adhering to these specifications ensures compliance with industry regulations and promotes a safer working environment, reducing the risk of accidents and ensuring regulatory compliance.

Improved Equipment Reliability and Performance:

These datasheets provide comprehensive information on equipment design, performance characteristics, and maintenance requirements. This knowledge enables better equipment selection, proactive maintenance planning, and optimization of equipment performance, leading to increased reliability and improved operational efficiency.

Efficient Project Management:

They also serve as valuable references during various project management activities. They facilitate design reviews, equipment installation, and commissioning processes, ensuring smooth project execution, timely completion, and efficient resource allocation.

Overall, process datasheets play a crucial role in ensuring efficient operations, effective decision-making, and the successful execution of industrial projects. They promote standardized communication, streamline procurement processes, enhance safety and compliance, improve equipment reliability, and contribute to efficient project management.

Applications and Uses of Process Datasheets in Industrial Operations

Process datasheets have wide-ranging applications across different industries. Here are some typical examples:

Chemical and Petrochemical Industry:

Process datasheets are crucial for equipment procurement in the chemical and petrochemical sector. They help specify details such as material compatibility, corrosion resistance, pressure ratings, and other critical factors specific to chemical processes.

Oil and Gas Industry:

In the oil and gas sector, process datasheets play a vital role in equipment selection for exploration, production, refining, and transportation. Datasheets for equipment like compressors, separators, pipelines, and storage tanks provide essential details regarding pressure ratings, materials, safety features, and environmental considerations.

Pharmaceutical and Biotechnology Industry:

Process datasheets are essential in the pharmaceutical and biotechnology industry, where adherence to regulatory standards is paramount. Datasheets for equipment such as sterilizers, bioreactors, filtration systems, and clean-rooms outline critical parameters like sterility requirements, temperature control, agitation systems, and documentation protocols.

Power Generation Industry:

Process datasheets find applications in the power generation sector for equipment such as turbines, generators, boilers, and control systems. These datasheets provide specifications related to power output, efficiency, fuel requirements, emissions control, and safety features.

Manufacturing Industry:

In the manufacturing industry, process datasheets are used for equipment such as conveyors, robotics, CNC machines, and industrial ovens. Datasheets in this field specify parameters like speed, load capacity, precision, control systems, and energy consumption.

Overall, process datasheets serve as valuable tools across various industries, ensuring accurate equipment selection, compliance with standards, and efficient operation of industrial processes.

The Generation Process of Process Datasheets in Industrial Operations

The generation of process datasheets involves collaboration between process engineers, mechanical engineers, and occasionally other disciplines like electrical and instrumentation. While the process engineer is typically responsible for preparing the datasheet, input and support from mechanical engineers are crucial. Design companies often have standardized templates for process datasheets specific to each type of equipment.

Process engineers fill out the process data in the standard templates based on information obtained from the Process Flow Diagram (PFD) or through calculations. This data includes parameters such as flow rates, temperatures, pressures, and capacity requirements. Mechanical engineers contribute equipment-specific details such as design codes, loading information, flange and nozzle requirements, and other mechanical specifications.

Process datasheets vary depending on the type of equipment, whether it is static or rotating equipment. Therefore, multiple process datasheets may need to be prepared for different equipment types within a project. As the data from the process datasheets is used for equipment design by manufacturers, it is crucial to thoroughly check and verify the information before sending it to the equipment vendor.

Process datasheets typically focus on critical items in the equipment or system while excluding insignificant details. This ensures that the datasheet provides essential and relevant data for equipment design and procurement purposes.

To prepare a comprehensive process datasheet, several documents and references are required. These include:

- Process P&ID (Piping and Instrumentation Diagram): The P&ID provides a visual representation of the process, including equipment, piping, and instrumentation. It serves as a primary reference for understanding the process flow and identifying the equipment associated with the datasheet.

- Process Flow Diagram (PFD): The PFD illustrates the overall process, including major equipment, streams, and their interconnections. It helps in determining process parameters and requirements for the datasheet.

- Equipment Design Codes: Design codes and standards specific to the industry and equipment type are essential references for ensuring compliance and safety. They provide guidance on design specifications, material selection, and construction requirements.

- Process Design Basis: The process design basis document outlines the fundamental parameters and criteria used to develop the process design. It includes information such as feed composition, operating conditions, product specifications, and process performance requirements.

- Industry Guidelines and Best Practices: Industry-specific guidelines, recommended practices, and standards play a significant role in developing process datasheets. These documents provide valuable insights into equipment selection, performance expectations, safety considerations, and operational requirements.

- Supplier Datasheets: Supplier datasheets from equipment manufacturers are valuable sources of technical information. They provide detailed specifications, performance data, and operating limits specific to the equipment being considered for procurement.

By incorporating information from these documents, process engineers can ensure that the process datasheet includes accurate and comprehensive data necessary for equipment selection, design, and procurement.

Conclusion

Process datasheets serve as indispensable tools for efficient and streamlined industrial operations across various sectors. These documents provide standardized and detailed information about equipment specifications, process parameters, and operational requirements, offering a multitude of benefits.

Across industries such as chemical, oil and gas, pharmaceutical, power generation, and manufacturing, process datasheets drive informed decision-making, ensure compliance with regulations, and support operational excellence. Embracing the use of process datasheets contributes to improved efficiency, productivity, and profitability in the ever-evolving industrial landscape.

Overall, process datasheets are vital tools that enable efficient communication, aid in procurement, enhance safety, and optimize performance in industrial operations. Their adoption leads to more effective decision-making, regulatory compliance, and improved overall productivity and profitability.