In today’s competitive age, both freshers and experienced engineering professionals are eager to upgrade their knowledge in piping engineering and oil & gas to become experts in the field. While there are numerous online piping engineering courses available, it’s essential to find the most effective ones that can truly develop one’s engineering skills. Although on-the-job learning is valuable, courses focusing on fundamental knowledge can help individuals bridge the gap between theory and practical work.

This article is specifically designed for those seeking reasonably priced online piping engineering courses. The following list comprises a variety of courses, and readers are free to choose any course that aligns with their interests. The article will be continuously updated as new piping engineering courses are discovered, providing ongoing value to readers.

Attending Piping Engineering Courses

To enroll in any of the mentioned courses, simply click on the provided links beneath each heading. Before proceeding, it’s recommended to read the course description, as it provides valuable information to determine if the course is suitable for individual requirements. Most of the courses offer course completion certificates, lifetime access to course materials, and downloadable resources.

Here is a breakdown of some of the courses mentioned:

Course: ASME B31.3 for a Pipe Stress Engineer

In this 1.5-hour course, you will gain a solid understanding of the fundamentals covered in the process piping code ASME B31.3, which is essential knowledge for any aspiring piping stress engineer. The course instructor has skillfully simplified the code’s technical language, making it easily accessible even for beginners. Throughout the course, you will cover the following key topics:

- Master the foundational concepts of ASME B31.3 required for pipe stress engineering

- Understand the scope and exclusions outlined in the ASME B31.3 code

- Explore the various factors leading to stress generation in piping systems

- Identify different types of piping stress, including sustained, expansion, and occasional stresses

- Learn the code equations commonly utilized in stress analysis software

- Familiarize yourself with the allowable values for different types of code stresses

- Understand material allowable stresses for effective pipe design

- Gain insights into reinforcement requirements for branch connections

- Acquire the skills to calculate pipe thickness in accordance with ASME B31.3 guidelines

This course offers a comprehensive foundation in ASME B31.3, empowering you to confidently pursue a career in pipe stress engineering. Enroll now to enhance your knowledge and proficiency in this critical aspect of piping engineering.

To join the course, click here, create your account, and then enroll.

Course: Become a Pro in Caesar II Pipe Stress Analysis

In this comprehensive five-hour course, the instructor is dedicated to providing a clear understanding of pipe stress analysis using the Caesar II software. The course covers the following key details to help you kickstart your journey in Caesar II pipe stress analysis:

- Mastery of Caesar II Software: Learn the ins and outs of using Caesar II, including navigating the software and its various functionalities.

- Creating a 3D Piping Model: Gain hands-on experience in building a 3D model of a piping system, incorporating piping, components, fittings, and supports.

- Equipment Connection Modeling: Understand the process of accurately modeling equipment connections within the Caesar II software.

- Fundamentals of Pipe Stress Analysis: Acquire a solid foundation in the basics of pipe stress analysis, including key concepts and methodologies.

- Load Case Preparation: Learn how to effectively prepare load cases, considering different operating conditions and scenarios.

- System Analysis and Result Review: Perform system analysis using Caesar II and develop the skills to interpret and review analysis results.

- Stress Critical Line List Preparation: Understand the importance of identifying and prioritizing stress critical lines within a piping system.

- Inputs and Outputs for Stress Analysis: Familiarize yourself with the necessary inputs and outputs required for conducting stress analysis.

- Wind and Seismic Analysis: Explore the essential aspects of wind and seismic analysis and their impact on piping systems.

- Utilizing Spring Hangers: Learn the proper utilization of spring hangers for effective pipe stress management.

- Model Editing Techniques: Acquire the ability to efficiently edit and modify your piping model within the Caesar II software.

By completing this course, you will develop a strong foundation in pipe stress analysis using Caesar II, empowering you to confidently tackle complex projects. Enroll now and embark on your journey to become proficient in pipe stress analysis with Caesar II.

Course: Pipe Support Engineering for Industrial Piping Systems

In this comprehensive two-hour online course, the instructor aims to address the often-neglected field of pipe support engineering by providing detailed explanations of the basics. By enrolling in this course, you will have the opportunity to learn the following key aspects:

- Role of Pipe Supports in Piping Design: Understand the critical role that pipe supports play in the overall design and functionality of piping systems.

- Types of Pipe Supports: Explore the different types of pipe supports commonly used in engineering projects, including their characteristics and applications.

- Pipe Support Spacing or Span: Learn about the factors that influence pipe support spacing and span, ensuring proper support for piping systems.

- Methods for Supporting Pipes: Gain insights into various techniques and strategies for effectively supporting pipes within a given system.

- Pipe Support Optimization Rules: Discover the optimization rules and guidelines that help achieve optimal pipe support design and performance.

- Standard and Special Pipe Supports: Familiarize yourself with both standard and specialized pipe support options available for specific project requirements.

- Pipe Support Engineering Considerations: Dive into the engineering considerations involved in designing and implementing pipe support systems, including factors such as load calculations, thermal expansion, and seismic considerations.

- List of Pipe Supports: Acquire knowledge about different types of pipe supports, their functions, and their specific applications, enhancing your understanding of available options.

By completing this course, you will gain a solid foundation in pipe support engineering, filling a gap in the available study material. Enhance your knowledge and skills in this essential aspect of piping design. Enroll now to expand your expertise in pipe support engineering fundamentals.

Course: FRP-GRP-GRE Piping/Pipeline Stress Analysis Using Caesar II

If you’re facing challenges in analyzing your FRP/GRP/GRE piping or pipeline system, this course is a must for you. The instructor has taken great care to explain the following aspects in simple language, enabling you to perform stress analysis with ease:

- Basics of FRP/GRE/GRP Piping Stress Analysis: Gain a solid understanding of the fundamental concepts involved in stress analysis of FRP/GRP/GRE piping systems.

- Gathering Inputs from Vendors: Learn about the essential inputs to acquire from vendors for conducting accurate stress analysis of FRP/GRP/GRE pipes.

- Modeling and Analysis in Caesar II: Explore the step-by-step process of effectively modeling and analyzing GRP/FRP/GRE piping systems using the Caesar II software.

- Flange Leakage Checking for FRP Piping Systems: Understand the methods and considerations for conducting flange leakage checking specifically for FRP piping systems.

- FRP Pipe Supporting Guidelines: Acquire valuable guidelines for properly supporting FRP pipes, ensuring their stability and structural integrity.

- Modeling and Analysis of FRP Piping System: Develop the skills necessary to proficiently model and analyze FRP piping systems, taking into account various factors and design considerations.

By enrolling in this course, you will gain the knowledge and practical insights needed to overcome challenges in analyzing FRP/GRP/GRE piping systems. Take the opportunity to enhance your expertise in stress analysis and ensure the optimal performance of these specialized piping materials.

If you are planning to join this course, click here to go to the page and enroll for the course.

Course: Pipeline Stress Analysis using Caesar II

In this concise 1.5-hour course, the instructor provides detailed explanations of the following contents:

- Liquid and Gas Pipeline Stress Analysis: Learn how to perform stress analysis on both liquid and gas pipelines using the industry-standard codes ASME B31.4 and ASME B31.8.

- Differentiating Piping and Pipeline: Understand the distinctions between piping and pipeline systems, including their specific characteristics and applications.

- Comparing ASME B31.4 and ASME B31.8: Explore the key differences between ASME B31.4 and ASME B31.8 codes, which govern the design and construction of liquid and gas pipelines.

- Utilizing Caesar II Software: Discover how to leverage the powerful Caesar II software for accurate and efficient pipeline stress analysis.

- Types of Pipelines: Gain insights into the various types of pipelines encountered in different industries, such as oil, gas, water, and more.

- Case Study of Pipeline Stress Analysis: Engage in a practical case study that demonstrates the application of pipeline stress analysis techniques to address a real-world problem.

- Modeling, Load Case Creation, Analysis, and Output Results: Learn the step-by-step process of modeling pipelines, creating load cases, conducting analysis, and interpreting output results using industry-standard practices.

By enrolling in this course, you will develop a solid understanding of stress analysis techniques specific to liquid and gas pipelines. Enhance your skills and knowledge to ensure the reliable and safe operation of pipeline systems.

Click here to visit the course page and enroll

Course: Buried or Underground Piping Stress Analysis using Caesar II

In this comprehensive course, participants will gain a thorough understanding of modeling and analyzing buried piping systems using the Caesar II software. The course covers the following key contents to facilitate effective learning:

- Modeling Buried Piping and Pipeline Systems: Learn the step-by-step process of accurately modeling buried piping and pipeline systems within the Caesar II software, ensuring proper representation of underground conditions.

- Load Case Creation Based on Codes: Understand how to create load cases in compliance with industry codes such as ASME B31.3, B31.4, and B31.8, considering the specific requirements for buried pipe stress analysis.

- Performing Underground/Buried Pipe Stress Analysis: Acquire the necessary skills to perform stress analysis for buried pipes, taking into account factors unique to underground installations.

- Reviewing Calculated Results: Interpret and analyze the results generated by the software, gaining insights into the stress levels and understanding their implications for buried piping systems.

- Inputs Required for Buried Pipe Stress Analysis: Learn about the essential inputs needed to conduct accurate and comprehensive stress analysis for buried pipes, ensuring the reliability and safety of the system.

- Creating a Buried Model: Discover the techniques for creating a detailed and realistic buried model, capturing the key aspects and parameters specific to buried piping systems.

By enrolling in this course, you will develop the expertise required to effectively model, analyze, and evaluate the stress levels of buried piping systems. Enhance your skills in buried pipe stress analysis using the industry-standard Caesar II software and ensure the optimal performance of underground installations.

Course: Learn Pump Piping Stress Analysis using Caesar II

In this comprehensive 3-hour course, participants will gain valuable knowledge in the following areas:

- Basics of Pipe Stress Analysis and Caesar II Software: Develop a strong foundation in pipe stress analysis principles and techniques, as well as become proficient in using the Caesar II software.

- Creating Load Cases: Learn how to create load cases specifically tailored for pump piping stress analysis within the Caesar II software.

- Fundamentals of Pump Piping Stress Analysis: Gain insights into the key considerations and techniques involved in analyzing stress in pump piping systems.

- Creating Load Cases for Pump Piping Analysis: Understand the process of creating load cases that accurately capture the operational conditions and loads specific to pump piping systems within the Caesar II software.

- Reading Isometrics for Piping System Modeling: Acquire the skill of reading isometrics to effectively model piping systems, ensuring accurate representation in the analysis.

- Analyzing Pump Data for Caesar II Modeling: Learn how to interpret pump general arrangement (GA) data and utilize it to model and analyze pump piping systems in the Caesar II software.

- Practical Case Study of Pump Piping Stress Analysis: Engage in a practical case study that provides real-world scenarios, allowing you to apply your knowledge and skills to analyze pump piping systems.

By enrolling in this course, you will enhance your understanding of pump piping stress analysis and develop proficiency in utilizing the Caesar II software for accurate modeling and analysis. Gain practical insights and the necessary skills to effectively address pump piping stress-related challenges.

Click here to enroll for this course

Course: Online Detailed Course on Piping Engineering (The Best Online Piping Engineering Course)

Comprehensive Online Piping Engineering Course for Complete Mastery

Immerse yourself in the best online piping engineering course available, offering a total of 210 lectures that cover every aspect of piping engineering. With the convenience of learning from home and enjoying unlimited access, this course is designed to provide in-depth knowledge delivered by a PMP-certified piping engineer with over 15+ years of industry experience in leading multinational companies.

The course is divided into four sections, each offering extensive coverage of essential topics:

- Section 1: Basics of Piping Engineering (9 Hours)

- Section 2: Piping Materials & Testing (6.5 Hours)

- Section 3: Piping Layouts (13 Hours)

- Section 4: Piping Stress Analysis (14 Hours)

Embark on a comprehensive journey to acquire a profound understanding of piping engineering, from foundational principles to advanced topics. Expand your expertise, strengthen your skills, and elevate your career prospects in the field of piping engineering with this exceptional course.

To access this course, click here.

Course: Comprehensive Online Pipe Stress Analysis Training

Discover one of the top-rated courses for detailed pipe stress analysis, meticulously prepared by industry experts. This course delves into the intricacies of pipe stress analysis, covering a wide range of crucial aspects. For direct communication with the course author and to clarify any doubts, you can reach out via WhatsApp at +91-9560191444. If you are specifically interested in the Online Piping Stress Analysis course, click here to explore the comprehensive topics covered.

Course: PG Diploma in Piping Design Engineering

Tailored for entry-level engineers and designers in piping engineering, this course offers a comprehensive understanding of various piping engineering aspects. Developed by esteemed experts, the course encompasses six modules, including Fundamentals of Piping, Equipment, Layout & Drawings, Design Calculations and Considerations, Piping Fabrication & Support, and Stress Analysis & Testing. Join this program to gain a holistic knowledge of piping engineering. To find out more and attend the course, click here.

Course: Introduction to Piping Engineering

Crafted by a highly experienced piping engineer with over 15+ years of industry expertise, this course serves as an ideal starting point for beginners. It provides a comprehensive introduction to piping engineering, covering vital topics such as the organizational structure of an EPC company, piping components, responsibilities of piping professionals, piping engineering deliverables, and interfaces with other departments. For detailed information about this course, click here to learn more.

Course: Piping Fabrication with Isometrics – Oil & Gas, Mechanical

Enhance your understanding of the piping fabrication process through detailed insights from piping isometric drawings. This four-hour course offers comprehensive knowledge on various aspects, including different isometrics, piping fabrication schedules, shop fabrication activities, welding basics, piping components, and relevant codes and standards. To learn more and attend this course online, click here.

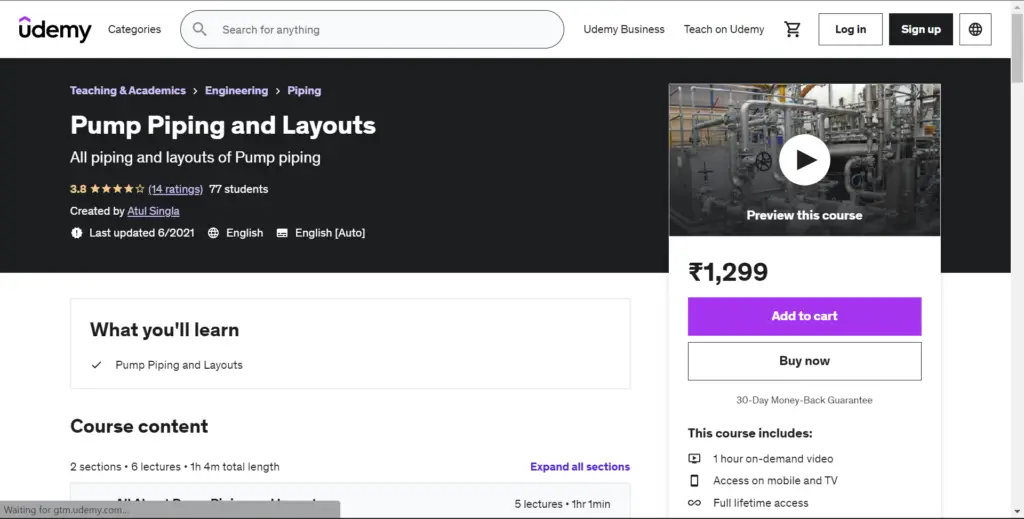

Course: Pump Piping and Layouts

Gain essential knowledge of piping design principles specific to pump piping routing and spacing with this indispensable course. Covering crucial topics such as pump piping components, layout aspects, spacing criteria, and stress recommendations, this course equips you with the necessary expertise. For more details and enrollment, click here.

Course: Column Piping and Layouts

Master the critical aspects of column piping and layouts, integral to refinery operations, with this concise 1.5-hour course. Learn about column functioning, layout considerations, nozzle orientation, platform and ladder requirements, as well as operational and maintenance aspects from industry experts. To explore further details and participate in this course, click here.

Course: Heat Exchangers – Piping Layouts

Deepen your understanding of piping design related to heat exchangers in this one-hour engineering course. Delve into all aspects of piping design for lines connected to heat exchangers, including construction and operating features of various exchangers. Additionally, gain insights into optimizing the layout. Join this course by clicking here.

Course: Rack Piping Design & Layout

Obtain a comprehensive overview of rack piping design and layout through this course. Learn about essential design inputs, pipe rack design concepts, guidelines for pipe placement on racks, pipe support, equipment, and platform considerations. Delve into the details and attend this course by clicking here.

Course: Overall & Unit Plot Plan

Discover the key aspects and parameters involved in creating an overall and unit plot plan through this informative video tutorial. Gain a comprehensive understanding of plot plan development and essential guidelines. To explore more and commence this course, click here.

Course: Compressor Piping and Layouts

Immerse yourself in the comprehensive coverage of compressor piping and layout aspects in this online piping engineering course. Gain insights into designing the layout of compressor piping systems and shelter design considerations. If you seek information on compressor piping layout, click here to join this course and enhance your knowledge.

Course. Understanding Piping Engineering in Oil and Gas IndustrY

Gain comprehensive insights into the world of piping engineering in the oil and gas industry through this informative course. Designed to establish a strong foundation in piping design, participants will learn key engineering deliverables specific to the oil and gas sector. This course covers essential topics including:

- Codes, Standards, and Specifications

- Piping Design Basis

- Piping Engineering Deliverables

- Piping Design Calculation

- Piping Supports

- Piping 3D Modeling

- Piping Tie-ins

- Piping Protection Coating and Insulation

Enroll now and access this course to develop a solid understanding of piping engineering practices in the context of the oil and gas industry. Click here to join and start your learning journey.

Course: Understanding Piping Components

Enhance your knowledge of piping components with this comprehensive course designed by highly experienced field experts. Explore every aspect of essential components such as pipes, fittings, olets, gaskets, flanges, bolting materials, valves, orifice flanges, spectacle blinds, steam traps, and more. Gain insights into their applications across power, oil & gas, refinery, and other process industries. Learn about:

- Common Piping Components used in Power, Oil & Gas, Refinery, and any other Process Industries.

- Materials, international codes, standards, specifications, manufacturing, inspection, and testing of piping components.

- Inspection and Testing of piping components in the workshop and at manufacturer locations.

Enroll and access this online course by clicking here.

Course: Mastering Piping Valves

Become an expert in piping valves with this in-depth course focusing on their usage in oil and gas piping. Delve into 18 types of valves, including standards, specifications, manufacturing, materials, inspection, and testing. Whether you’re starting with the basics or seeking advanced knowledge, this video course covers all aspects of valves used in process plant piping. Enroll now and access this comprehensive online course by clicking here.

Course. Overview of the Oil and gas industry

Immerse yourself in the captivating history and unique characteristics of petroleum with this specially crafted course.

This video course will briefly cover the following aspects:

- Oil in Our Economic Life

- The Characteristics of the Oil Industry

- History of the Oil Industry and Petroleum Refining in Brief

- Energy Oil and Economic Development

- Energy Consumption Forecast

- Energy resources

- Production of Oil and Gas

- Major Players in the Oil Industry

- Investments

- Profitability

- Conclusion

To Access and enroll for this video tutorial course click here

Course. Elements of Piping Engineering

Organized into eight detailed sections comprising 36 lectures, this comprehensive piping design course covers various aspects of piping engineering. Topics include the scope of piping engineering, oil and gas project life cycle, piping design basis, process interface, different piping systems, valve and flange types, strainer and steam trap details, and more.

Access this course and gain in-depth knowledge by clicking here.

Course: Module on Rack Piping, Pump Piping, Heat Exchanger Piping, Compressor Piping, and Column Piping

Explore the fundamental philosophies and best practices for rack piping, pump piping, heat exchanger piping, compressor piping, and column piping in this five-hour-long course.

You can find out more about what this module covers and join the course by clicking here.

Course: Valve Inspection and Testing

Concerned about valve performance? Learn the basics of valve inspection and testing through this informative course. Discover essential techniques and procedures to ensure optimal valve operation. Click here to learn more about the course and attend at your own pace.

Course: Piping Codes and Standards

Embark on your journey as a piping professional by familiarizing yourself with the codes and standards that govern piping engineering design and fundamentals. This course is perfect for beginners seeking a solid foundation in the industry. Click here to understand the codes covered in this course and join today.

Course: Piping Wall Thickness Calculation

Designing your piping system and need to determine the appropriate wall thickness? This course provides step-by-step methods for calculating pipe thickness based on pressure and temperature requirements. Gain the necessary skills by clicking here to explore more details about pipe thickness calculation methodologies.