Pipeline Stress Analysis is a crucial process in assessing the mechanical behavior of pipelines under various operating conditions. It involves using specialized software like Caesar II to model and calculate stresses, strains, and deformations. This analysis helps identify potential problem areas and ensures the pipeline’s structural integrity.

Pipeline Stress Analysis plays a vital role in the design, construction, and operation of pipelines, especially those with high-pressure and high-temperature conditions. Specialized software is utilized to model the pipeline and calculate the stresses, strains, and deformations it may undergo under various loads.

By identifying potential issues in the pipeline design and recommending necessary modifications, this analysis ensures the pipeline’s structural integrity. Ultimately, Pipeline Stress Analysis is crucial for safe and reliable pipeline operation, reducing the potential risks of leaks, ruptures, and other failures that could have severe consequences for the environment, economy, and human safety.

Introduction to Caesar II

Caesar II is a widely used software in the oil and gas industry for pipeline stress analysis. It is developed and marketed by Hexagon PPM, a global software company that specializes in providing engineering design and analysis software solutions.

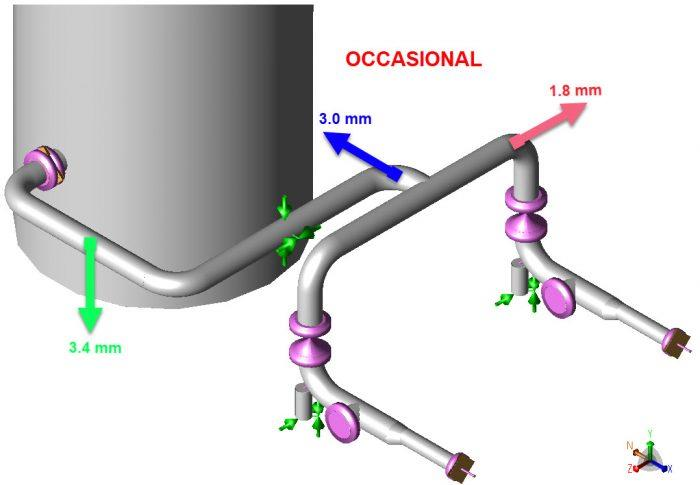

Being a powerful software, it utilizes finite element analysis (FEA) to model and analyze pipelines, pressure vessels, and piping systems. It enables engineers to simulate and understand system behavior under different operating conditions like pressure, temperature, and external loads. The software calculates stresses, strains, and deformations, comparing them to industry standards for compliance and safety.

Engineers benefit from CAESAR II’s user-friendly interface, allowing easy input of design parameters, 3D result visualization, and identification of potential problem areas. The software offers modeling tools for various components like valves, fittings, and flanges, and enables analysis of factors such as thermal expansion, seismic events, wind loads, and more. Overall, CAESAR II empowers engineers in effectively analyzing pipeline systems and ensuring their integrity and adherence to regulations.

Importance of Pipeline Stress Analysis

Pipeline Stress Analysis is crucial for guaranteeing the safety, dependability, and durability of pipelines, which are vital components across industries like oil and gas, water supply, and chemical processing. Here are some key reasons why Pipeline Stress Analysis holds significant importance:

- Safety: Pipelines transport hazardous substances, including oil, gas, and chemicals. Any failure or rupture poses serious risks to human lives, the environment, and property. Through Pipeline Stress Analysis, potential failure points can be identified, ensuring pipelines are designed to operate within safe limits.

- Reliability: Pipelines are exposed to various loads such as temperature fluctuations, pressure changes, and external forces like wind and earthquakes. These loads can subject the pipeline to excessive stress, leading to fatigue, cracks, and leaks over time. Pipeline Stress Analysis assesses whether the pipeline can withstand these loads, enabling reliable operation without failures or interruptions.

- Compliance: Pipelines must stick to industry standards, codes, and regulations such as the ASME B31 series to ensure their safety and reliability. Pipeline Stress Analysis ensures pipelines meet these requirements, preventing penalties, lawsuits, and reputational damage.

- Cost-effectiveness: By identifying potential design flaws or inefficiencies, Pipeline Stress Analysis helps minimize maintenance costs, repair expenses, and downtime. Optimization of pipeline design, materials, and operating parameters through analysis leads to cost reduction while maintaining safety and reliability.

In conclusion, Pipeline Stress Analysis is one of the many critical steps in the design, construction, and operation of pipelines. Its usage ensures pipelines are safe, reliable, compliant, and cost-effective, reducing risks to individuals, the environment, and businesses.

Contents of a Pipeline Stress Analysis Course

In the Pipeline Stress Analysis Course for beginners, you will gain knowledge in the following areas:

- Differentiating between piping and pipeline: Understand the distinctions between piping systems and pipelines.

- Types of Pipelines: Explore various types of pipelines used in different industries and applications.

- Pipeline Stress Analysis Selection Criteria: Learn the factors to consider when selecting appropriate methods for pipeline stress analysis.

- ASME B31.4 vs ASME B31.8: Understand the major differences between ASME B31.4, which covers liquid pipelines, and ASME B31.8, which pertains to gas pipeline codes.

- Modeling of Pipeline in Caesar II Software: Discover the step-by-step process involved in modeling a pipeline system using Caesar II software for analysis.

- Creating Analysis Load Cases: Generate the necessary load cases for conducting specific pipeline system analyses.

- Analyzing and studying the results: Learn how to interpret and study the analysis results to assess the pipeline system’s stress viability.

- Stress Mark-up and Report Preparation: Gain insights into marking necessary changes and preparing comprehensive reports based on the analysis findings.

By completing this course, you will develop a foundation in pipeline stress analysis and be equipped with practical skills to effectively evaluate pipeline systems using Caesar II software.

How to Join the Pipeline Stress Analysis Course

- Click here to visit the page containing the pipeline stress analysis course.

- Click on Add to cart or buy now.

- Create your account, make payments, and enjoy the course