A Pig Signaller, also referred to as a pig detector, is a crucial device utilized in the oil and gas industry. Its primary function is to detect the movement of a pipeline inspection gauge, commonly known as a “pig.” This specialized tool is employed for various purposes, such as cleaning, inspecting, or measuring the interior of pipelines. By being propelled through the pipeline using the fluid flow, pigs play a vital role in pipeline maintenance. Pig Signallers are instrumental in identifying the presence and successful passage of pigs within the pipeline system.

To ensure efficient pipeline operations, the pig signaller is typically installed at strategic points along the pipeline, such as valve stations or the receiving end. When a pig passes through, the signaller detects its movement and promptly relays this information to the control room. This signal not only confirms the successful passage of the pig but also provides valuable details regarding its location and speed.

The data collected by the pig signaller holds significant importance for pipeline operators. It enables them to closely monitor the pipeline’s condition and promptly identify any potential issues such as corrosion, cracks, or other forms of damage that may necessitate maintenance or repair. By conducting regular inspections and employing pigs and pig signallers, pipeline operators can uphold the safety and efficiency of oil and gas transportation.

Exploring the Different Types of Pig Signallers for Effective Pipeline Monitoring

In oil and gas industries, different types of pig signallers are put in use to monitor pipelines effectively. Here are some commonly used types:

- Mechanical Pig Signaller: This type relies on a mechanical trigger mechanism that detects the pig’s passage. When the pig makes contact with a physical arm or lever, it activates the trigger, sending a signal to the control room.

- Magnetic Pig Signaller: Magnetic pig signallers utilize a magnetic field to identify the pig’s movement. Equipped with a magnet, the pig disrupts the magnetic field as it passes by the signaller, triggering a signal to the control room.

- Acoustic Pig Signaller: This type of pig signaller employs sound waves to detect the pig’s passage. The pig here is equipped with a transmitter that emits an acoustic signal, which is picked up by the signaller. This acoustic signal is then used to trigger a notification in the control room.

- Optical Pig Signaller: Optical signallers use optical sensors to detect the pig’s movement. The pig is outfitted with a reflective or fluorescent material, and as it passes the signaller, the optical sensor detects the change in light, subsequently sending a signal to the control room.

Each type of pig signaller possesses its own set of advantages and disadvantages, which depend on factors such as the pig’s characteristics, pipeline size and material, and operating conditions. Pipeline operators carefully select the appropriate pig signaller based on these considerations to ensure optimal performance and safety during pipeline monitoring activities.

Intrusive vs Non-intrusive Pig Signallers

Pig signallers in pipeline monitoring are further categorized as intrusive and non-intrusive types:

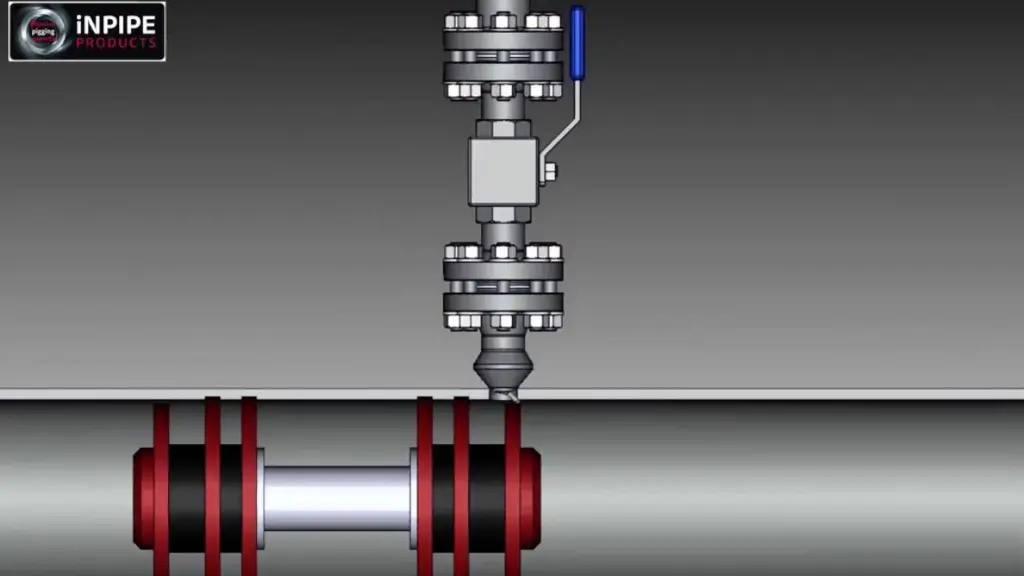

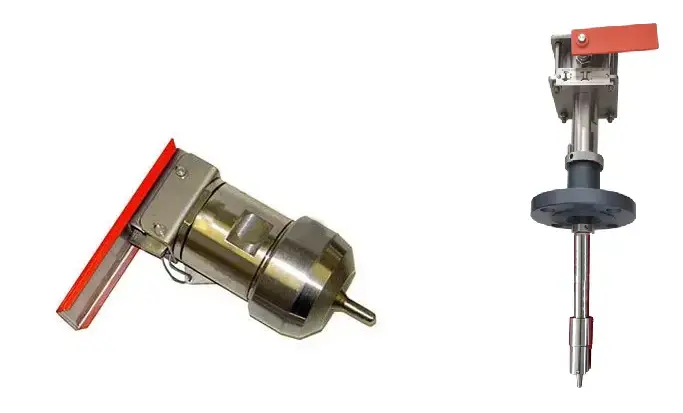

Intrusive Pig Signallers: These signallers are installed inside the pipeline and physically interact with the passing pig. They can be mechanical switches, magnets, or sensors that trigger a signal upon contact with the pig. Special fittings may be required for their installation and removal, allowing access to the pipeline.

Non-intrusive Pig Signallers: Unlike intrusive signallers, non-intrusive ones do not physically interact with the pig. They engage external sensors or detectors to detect the pig’s passage through the pipeline. Several methods, such as ultrasonic sensors, RFID tags, or acoustic detectors, can be utilized for this purpose.

Choosing between intrusive and non-intrusive pig signallers depends on a number of factors, including the pig type, pipeline size and material, and operating conditions. Generally, non-intrusive signallers are easier to install and maintain but may be less accurate or reliable. In contrast, intrusive signallers offer greater accuracy and reliability but involve more complex installation and potentially carry a higher risk of pipeline damage.

The key differences between intrusive and non-intrusive pig signallers include:

- Installation: Intrusive signallers require fitting installation inside the pipeline, while non-intrusive ones are installed externally without modifying the pipeline.

- Interaction with Pig: As mentioned before, intrusive pig signallers physically interact with the passing pig, while non-intrusive signallers do not.

- Accuracy: While Intrusive signallers provide more precise and reliable pig detection, non-intrusive signallers may have a higher risk of false alarms or missed detections.

- Maintenance: Intrusive signallers typically require more maintenance and carry a greater risk of pipeline damage, while non-intrusive signallers are generally easier to maintain and less likely to cause harm.

- Cost: Intrusive signallers tend to be more expensive in terms of installation and maintenance, while non-intrusive signallers are usually more cost-effective.

The choice between intrusive and non-intrusive pig signallers depends on several factors, and pipeline operators must consider the specific requirements of their operation to make an informed decision.

Key Components of a Pig Signaller for Pipeline Monitoring

In the realm of pipeline monitoring, pig signallers consist of several key components that may vary based on the type and manufacturer. Here are the fundamental components typically found in a pig signaller:

- Housing: The housing serves as the protective outer casing, safeguarding the internal components from environmental factors.

- Trigger Mechanism: The trigger mechanism detects the pig’s passage and initiates a signal to the control room. The specific type of trigger mechanism varies depending on the pig signaller type discussed earlier.

- Signal Transmitter: This component transmits a signal to the control room, indicating the successful passage of the pig. The signal can be transmitted through wires, radio frequency, or other appropriate means based on the pig signaller’s design.

- Battery: A battery, located within the housing, provides the necessary power to the pig signaller. It can be rechargeable or replaceable, depending on the specific pig signaller type.

- Control Circuitry: The control circuitry manages the signals and power supply within the pig signaller. It often comprises microprocessors, amplifiers, filters, and other electronic components.

- Mounting Hardware: The mounting hardware facilitates the attachment of the pig signaller to the pipeline or valve station. It typically includes clamps, brackets, or other relevant mounting devices.

Additionally, pig signallers may incorporate extra features like tamper-evident seals, remote monitoring capabilities, and alarms to promptly notify operators of potential issues or failures.

While the specific components may differ, the collective functionality of these elements ensures the pig signaller’s effectiveness in monitoring pipeline activities.

Discovering the Materials Used in Pig Signallers for Pipeline Monitoring

Pig signallers are constructed from materials chosen to withstand the demanding environments and conditions encountered during pipeline monitoring. While material selection may vary depending on the specific application, here are some commonly used materials:

- Stainless Steel: Known for its durability and resistance to corrosion, stainless steel is frequently employed in pig signallers. It can withstand high temperatures, pressures, and is easily maintained.

- Aluminum: Aluminum, prized for its lightweight nature, is often used for pig signallers mounted on pipelines or valve stations. It offers corrosion resistance and can endure elevated temperatures.

- Plastic: For lightweight, portable pig signallers that require impact resistance and chemical resistance, plastic is a preferred choice. It can be molded into various shapes, exhibits corrosion resistance, and withstands harsh conditions.

- Brass: Brass finds application in pig signallers deployed in offshore environments due to its corrosion resistance to saltwater exposure. With good electrical conductivity and ease of machining, it serves as a reliable material.

- Carbon Steel: Pig signallers necessitating resilience against high pressures and temperatures frequently employ carbon steel. It boasts corrosion resistance and is commonly utilized in oil and gas pipelines.

Material selection for pig signallers depends on factors like operating conditions, pig type, and desired lifespan of the signaller. By carefully considering these variables, pipeline operators can choose the appropriate material that ensures the longevity and functionality of the pig signaller.

Pig Signaller Purchase Specification

When specifying a pig signaller for procurement, it’s crucial to take the following factors into account:

- Type of Pig: Consider the specific type of pig that will be utilized in the pipeline, including its size, shape, and material. This information will help determine the appropriate trigger mechanism and signal transmitter required for the pig signaller.

- Trigger Mechanism: Ensure that the chosen trigger mechanism is suitable for the intended application and capable of reliably detecting the pig’s passage through the pipeline.

- Signal Transmission: Evaluate the method of signal transmission to ensure it is suitable for the specific application and the distance between the pig signaller and the control room.

- Pipeline Size and Material: Consider the size and material of the pipeline as they will influence the size and strength of the mounting hardware required for the pig signaller. Additionally, larger pipelines may necessitate more robust signal transmitters.

- Operating Conditions: Take into account the operating conditions of the pipeline, such as temperature, pressure, and fluid corrosiveness. These factors will impact the materials and components needed for the pig signaller. For example, in harsh environments like offshore pipelines, corrosion-resistant materials like stainless steel or brass may be preferred.

- Environmental Conditions: Environmental factors such as humidity, moisture, and exposure to UV radiation should also be considered. If the pig signallers are to be used in outdoor environments, it may need to be weatherproof and have protective coatings to withstand the elements.

- Compliance Requirements: Check if the pig signaller needs to comply with any specific regulations, safety standards, or industry guidelines based on the application and location. Consult with regulatory agencies and industry associations to ensure compliance.

Providing extensive details about the pipeline and operating conditions when specifying a pig signaller will help ensure the selection of an appropriate solution. Manufacturers or suppliers of pig signallers can also offer valuable guidance on suitable specifications based on the provided information.

Installation Guidlines

When installing a pig signaller, it’s crucial to adhere to the specific guidelines provided by the manufacturer.

Some of the general installation guidelines to follow include:

- Select the Appropriate Location: Choose a location that allows easy access for maintenance and monitoring. Typically, the pig signaller should be installed upstream of the pig launcher or receiver.

- Prepare the Installation Site: Ensure the installation site is clean, dry, and free from debris or obstructions. Securely mount the pig signaller using suitable mounting hardware.

- Connect the Signal Transmission: Follow the manufacturer’s instructions to connect the signal transmission. This may involve wiring, radio frequency, or other communication methods specified by the pig signaller.

- Connect the Power Source: Properly connect the power source as instructed by the manufacturer. This may involve batteries or external power sources, depending on the pig signaller’s design.

- Test the Pig Signaller: Conduct comprehensive testing to verify the pig signaller’s functionality. This may include functional tests or pressure tests to ensure proper operation.

- Monitor the Pig Signaller: Regularly observe the pig signaller to ensure it continues to function correctly. This proactive approach helps detect any potential issues that may require maintenance or adjustments.

It is very important to strictly adhere to the manufacturer’s installation guidelines to ensure correct installation and optimal performance. Additionally, it is crucial to meet any applicable regulations and standards throughout the installation process.

Pig Signaller Manufacturers

There are numerous manufacturers of pig signallers, including:

- T.D. Williamson

- Pigs Unlimited International

- Enduro Pipeline Services

- Rosen Group

- NDT Global

- Pigtek Ltd.

- Baker Hughes

- MISTRAS Group

- Clock Spring

- Pipeline Engineering & Supply Co. Ltd.

It’s worth noting that this is not a complete list, and that there may be other manufacturers of pig signallers as well.

Price of a Pig Signaller

The price of pig signallers can significantly vary based on factors such as type, model, manufacturer, pipeline specifications, and operating conditions. Intrusive pig signallers generally tend to be more expensive than non-intrusive pig signallers due to their additional installation and maintenance requirements.

Several factors can influence the cost of pig signallers, including pipeline size, material, and the complexity of the pig signaller’s design. Additionally, operating conditions, such as temperature, pressure, and fluid corrosiveness, may impact the materials and components required, consequently affecting the overall cost.

As a rough estimate, non-intrusive pig signallers typically range from a few hundred dollars to several thousand dollars, while intrusive pig signallers can range from several thousand dollars to tens of thousands of dollars. However, it’s important to note that these figures are approximate, and the actual cost of a pig signaller will depend on specific requirements and customization.

To obtain accurate pricing information, it’s advisable to consult reputable manufacturers or suppliers who can provide detailed quotations based on the specific needs and specifications of the pipeline monitoring project. They can offer guidance and expertise to help select the most suitable pig signaller within the desired budget.