In the realm of ocean engineering, where the demands for robust and reliable connections are paramount, the lap joint flange emerges as an essential component. This type of flange is designed to provide a flexible and effective solution for connecting pipelines and equipment in marine environments. Its unique design and functionality make it particularly suited for the challenges posed by ocean engineering projects. This blog will delve into the specifics of the lap joint flange, its applications, and provide insights through case studies that highlight its importance in ocean engineering.

Lap Joint Flange: Design and Functionality

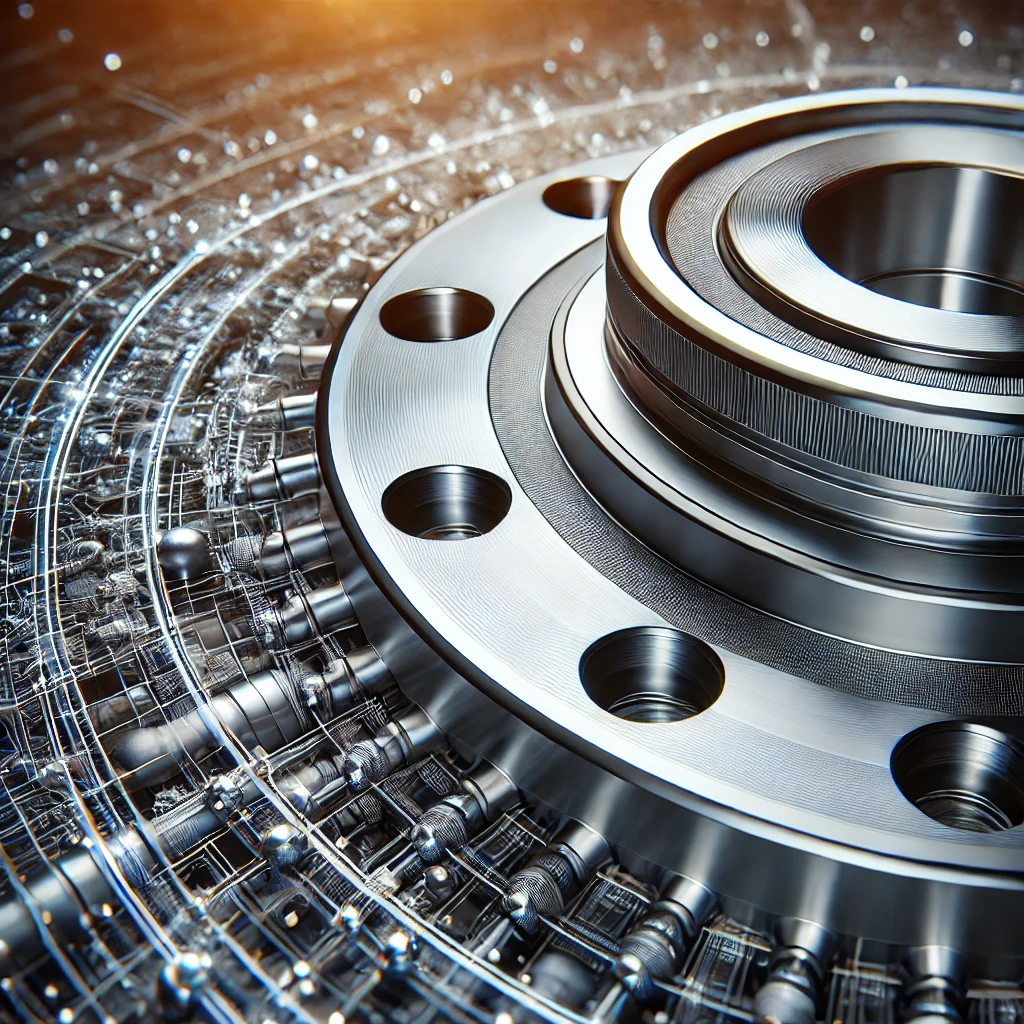

A lap joint flange, also known as a Van Stone flange, is an essential component in piping systems, particularly valued for its flexibility and ease of maintenance. It consists of two main parts: the stub end and the backing flange. This assembly is specifically designed to provide a reliable yet adjustable connection between pipes.

Components and Materials

- Stub End: The stub end is the component welded to the pipe. It has a short piece of pipe with a flat end that interfaces with the backing flange. Stub ends are typically made from materials that match or are compatible with the piping system to ensure uniformity in thermal expansion, corrosion resistance, and mechanical strength. Common materials include carbon steel, stainless steel, and various alloys.

- Backing Flange: The backing flange, which is free to rotate around the stub end, provides the clamping force needed to hold the joint together. This rotation allows for easier alignment during installation. Backing flanges are usually made from materials with good mechanical properties, such as carbon steel or stainless steel, and can be coated or treated to enhance corrosion resistance.

Design Advantages

The lap joint flange design offers several advantages:

- Ease of Alignment and Installation: The primary benefit of the lap joint flange is its rotational capability, which allows for quick and precise alignment of bolt holes. This is particularly advantageous during assembly, as it reduces the time and effort required to align the flange with the mating component.

- Flexibility and Adjustability: The ability to rotate the backing flange around the stub end provides flexibility in installation, especially in systems where frequent disconnection and reconnection of pipes are necessary. This feature is invaluable in complex piping networks where space constraints and alignment challenges are common.

- Maintenance and Replacement: In applications where maintenance is frequent, the lap joint flange simplifies the process of disassembly and reassembly. Since the backing flange is not welded to the pipe, it can be reused when sections of the pipe or the stub end need to be replaced. This reduces material costs and downtime.

Key Features and Advantages of Lap Joint Flange

- Ease of Installation and Alignment: The primary advantage of the lap joint flange is its ability to rotate around the stub end. This feature simplifies the alignment process, reducing the time and effort required for installation.

- Flexibility: The lap joint flange’s design allows for slight movement and adjustment, accommodating misalignment and thermal expansion in pipelines. This flexibility is crucial in ocean engineering, where pipelines are subject to dynamic forces and temperature variations.

- Reduced Maintenance Costs: The ability to easily disassemble and reassemble the flange makes maintenance operations more straightforward and less costly. This is particularly beneficial in ocean engineering, where access to equipment can be challenging.

- Corrosion Resistance: Lap joint flanges are often made from materials that resist corrosion, such as stainless steel or alloys. This is vital for marine applications, where exposure to seawater and harsh environmental conditions is constant.

Applications in Ocean Engineering

In ocean engineering, the lap joint flange finds applications in various sectors, including:

- Offshore Oil and Gas Platforms: The harsh conditions of offshore environments necessitate the use of robust and flexible pipeline connections. Lap joint flanges are employed in the construction of pipelines and risers, providing reliable connections that can withstand the dynamic forces encountered at sea.

- Underwater Pipelines: The installation and maintenance of underwater pipelines require connections that are easy to align and disconnect. Lap joint flanges facilitate these operations, ensuring the integrity and reliability of subsea pipelines.

- Marine Renewable Energy Projects: In projects involving tidal and wave energy converters, lap joint flanges are used to connect various components. Their flexibility and ease of maintenance make them ideal for the dynamic and corrosive marine environment.

Case Study 1: Offshore Oil Platform in the North Sea

An offshore oil platform in the North Sea faced significant challenges due to the harsh environmental conditions, including strong currents, high waves, and severe weather. The platform’s pipeline system required frequent maintenance and occasional replacement of sections due to wear and corrosion.

The engineers decided to use lap joint flanges for the pipeline connections. The flanges’ ability to rotate allowed for easy alignment during installation, significantly reducing the time required for assembly. Additionally, the corrosion-resistant materials used for the flanges ensured a longer lifespan for the connections, reducing the frequency of maintenance operations.

The implementation of lap joint flanges resulted in a more reliable pipeline system with lower maintenance costs and increased operational efficiency. The flexibility of the flanges also helped to accommodate the dynamic forces exerted on the pipelines, enhancing their overall durability.

Case Study 2: Subsea Pipeline Installation in the Gulf of Mexico

In the Gulf of Mexico, a major subsea pipeline installation project aimed to transport natural gas from an offshore platform to an onshore processing facility. The project faced several challenges, including deep-water installation, strong currents, and the need for high-precision alignment of the pipeline sections.

The project team opted to use lap joint flanges for the pipeline connections. The flanges’ ability to be easily aligned and their flexibility in accommodating slight movements were crucial for the successful installation of the pipeline in the deep-water environment.

During the installation process, the lap joint flanges allowed the engineers to make precise adjustments, ensuring a secure and leak-free connection between the pipeline sections. The project was completed on time and within budget, with the lap joint flanges playing a key role in achieving these objectives.

Case Study 3: Tidal Energy Converter in Scotland

A tidal energy project off the coast of Scotland aimed to harness the power of tidal currents to generate renewable energy. The project involved the installation of tidal energy converters, which required robust and flexible connections to withstand the dynamic forces of the marine environment.

The engineers chose lap joint flanges for connecting the various components of the tidal energy converters. The flanges’ ease of installation and maintenance, along with their ability to accommodate thermal expansion and misalignment, made them an ideal choice for this application.

The use of lap joint flanges ensured the reliable operation of the tidal energy converters, minimizing downtime and maintenance costs. The project’s success demonstrated the effectiveness of lap joint flanges in marine renewable energy applications.

The lap joint flange is an indispensable component in ocean engineering, offering numerous advantages such as ease of installation, flexibility, reduced maintenance costs, and corrosion resistance. Its applications in offshore oil and gas platforms, underwater pipelines, and marine renewable energy projects highlight its versatility and reliability.

Through the case studies presented, it is evident that lap joint flanges play a crucial role in ensuring the success of ocean engineering projects. Their unique design and functionality make them well-suited to the challenges posed by the marine environment, providing robust and flexible connections that enhance the overall performance and longevity of pipeline systems.

As ocean engineering continues to evolve, the lap joint flange will remain a vital component, contributing to the development of more efficient, reliable, and sustainable marine infrastructure. Whether it is in the installation of subsea pipelines, the construction of offshore platforms, or the deployment of renewable energy systems, the lap joint flange will continue to be a cornerstone of ocean engineering innovation.