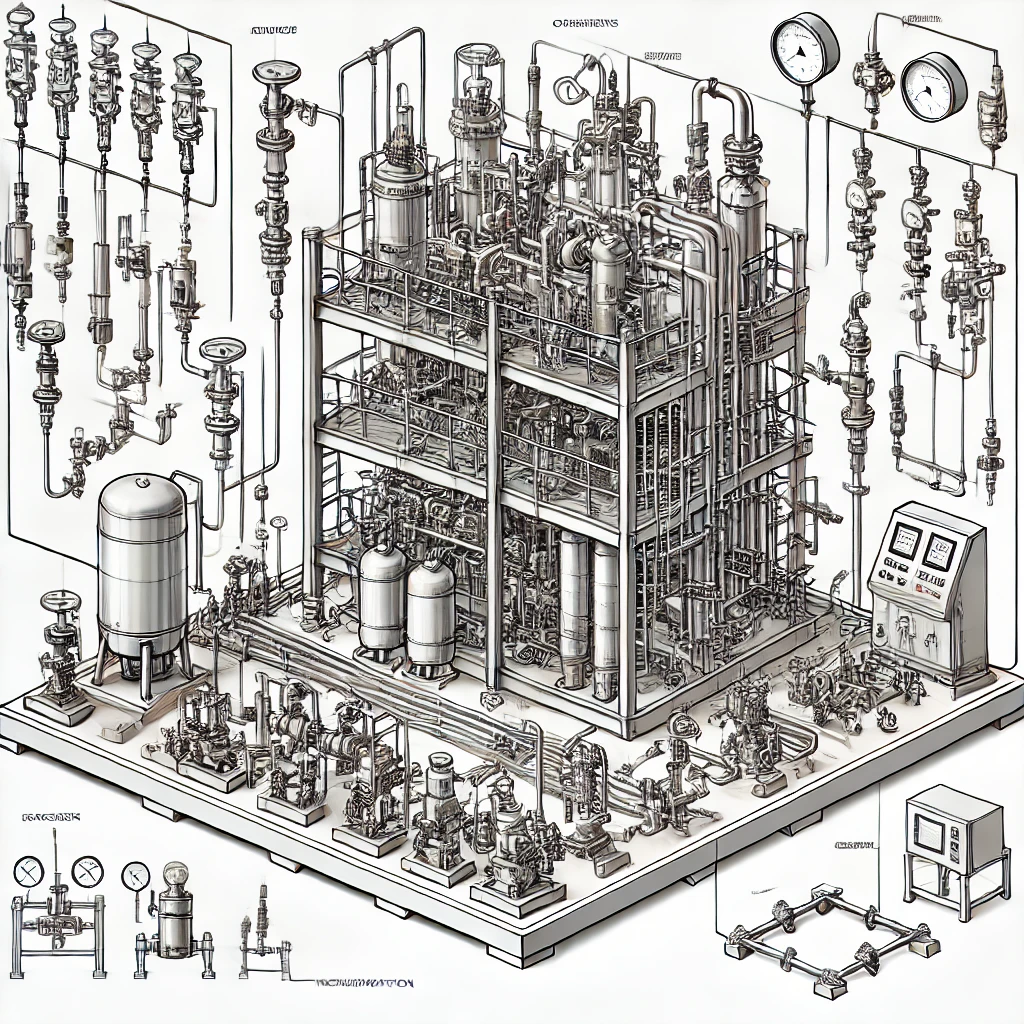

Modular process skids are prefabricated units that integrate all necessary components for a particular process into a single, compact module. These skids are designed and assembled in a controlled environment, which ensures high-quality fabrication and simplifies the on-site installation process. The skid typically includes piping, valves, instrumentation, control systems, and sometimes even the structural framework. Once assembled and tested, the skid is transported to the operational site, where it can be quickly installed and commissioned. This modular approach is increasingly favored in various industries due to its numerous benefits, including reduced installation time, cost savings, and improved safety.

Characteristics of Modular Skid Design

Compactness

Modular skids are designed to occupy minimal space while maximizing functionality. This compact design is particularly beneficial in environments where space is at a premium, such as offshore platforms and urban industrial sites.

Pre-engineering and Pre-fabrication

One of the key features of modular skids is that they are pre-engineered and pre-fabricated in a controlled environment. This approach allows for precise control over the manufacturing process, ensuring that all components meet stringent quality standards before arriving on-site.

Flexibility and Scalability

Modular skids are highly flexible and can be easily modified or expanded to accommodate process changes or increased capacity. This scalability makes them an attractive option for industries that anticipate growth or need to adapt to changing market demands.

Quality Control

Fabrication in a controlled environment ensures higher quality and adherence to standards. The controlled setting allows for rigorous testing and inspection of each component, leading to more reliable and consistent performance.

Ease of Maintenance

Modular skids are designed with maintenance in mind. Components are easily accessible, which simplifies routine maintenance and inspections. This accessibility reduces downtime and maintenance costs over the lifespan of the skid.

Integration

Advantages of Modular Process Skids

Reduced Installation Time

Since modular skids are pre-assembled and tested off-site, the time required for on-site installation is significantly reduced. This expedited installation process minimizes disruption to existing operations and allows for quicker commissioning of new systems.

Cost-Effective

The off-site fabrication and pre-assembly of modular skids result in lower labor costs and minimized on-site construction risks. These factors contribute to overall cost savings, making modular skids a cost-effective solution.

Minimized Disruption

Off-site construction of modular skids minimizes disruption to existing operations during installation. This approach is particularly beneficial in environments where continuous operation is critical, such as chemical plants and refineries.

Improved Safety

Fabrication in a controlled environment reduces exposure to hazardous site conditions, enhancing overall safety. Additionally, the pre-tested nature of modular skids ensures that potential issues are identified and resolved before installation.

Consistent Quality

Higher control over manufacturing processes leads to more consistent and reliable quality. Each skid is subject to rigorous testing and inspection, ensuring that it meets or exceeds industry standards.

Simplified Logistics

Modular skids are easier to transport and install compared to large, complex systems. The compact and self-contained nature of skids simplifies logistics, reducing transportation costs and facilitating easier handling on-site.

Modular skids can be seamlessly integrated with existing systems or other skids to form a larger process system. This integration capability makes them a versatile solution for complex industrial processes.

Applications of Modular Process Skids

Chemical Processing

Modular process skids are widely used in the chemical processing industry for applications such as mixing, blending, and chemical reactions. Their compact design and ease of integration make them ideal for various chemical processes.

Pharmaceuticals

In the pharmaceutical industry, modular process skids are used for drug manufacturing and formulation. Their high-quality construction and stringent quality control standards ensure compliance with regulatory requirements.

Food and Beverage

The food and beverage industry utilizes modular skids for the production and processing of food and beverages. These skids can handle tasks such as mixing, pasteurization, and packaging, providing a reliable and efficient solution.

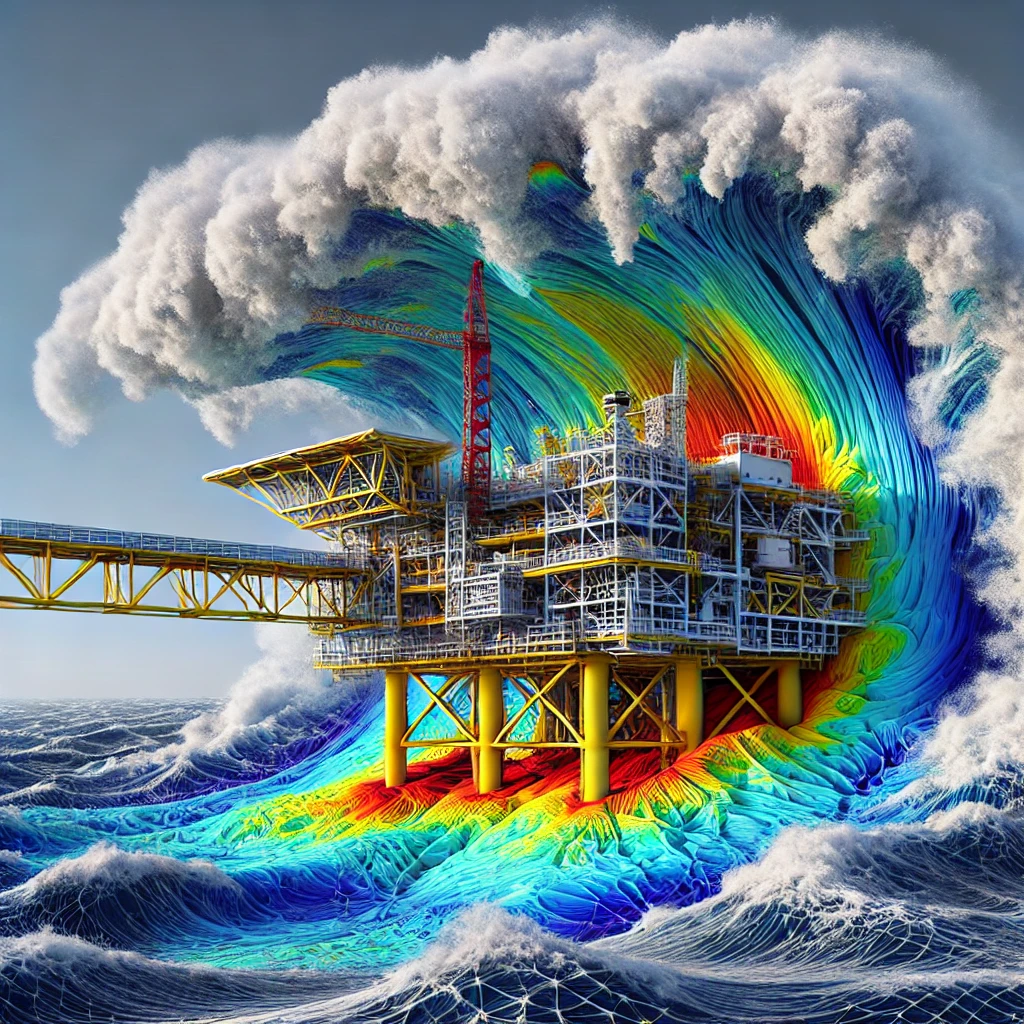

Oil and Gas

Modular process skids are deployed in the oil and gas industry for refining, treatment, and processing of oil and gas. Their robust construction and ability to withstand harsh environments make them suitable for both onshore and offshore applications.

Water Treatment

In water treatment plants, modular process skids are used for water purification and wastewater treatment processes. Their compact design and ease of maintenance make them an ideal choice for both municipal and industrial water treatment.

Power Generation

The power generation industry employs modular skids in auxiliary systems for power plants. These skids can handle tasks such as fuel handling, water treatment, and emissions control, contributing to the overall efficiency and reliability of power generation operations.

Modular Skid Design in Ocean Engineering

Importance in Offshore Operations

In ocean engineering, modular process skids play a crucial role in offshore oil and gas operations. The harsh marine environment demands robust and reliable equipment, which modular skids provide due to their pre-tested and high-quality construction.

Applications in Offshore Drilling Platforms

On offshore drilling platforms, modular skids are used for drilling fluid processing, water treatment, and chemical injection systems. Their compact design and ease of installation make them well-suited for the limited space available on platforms.

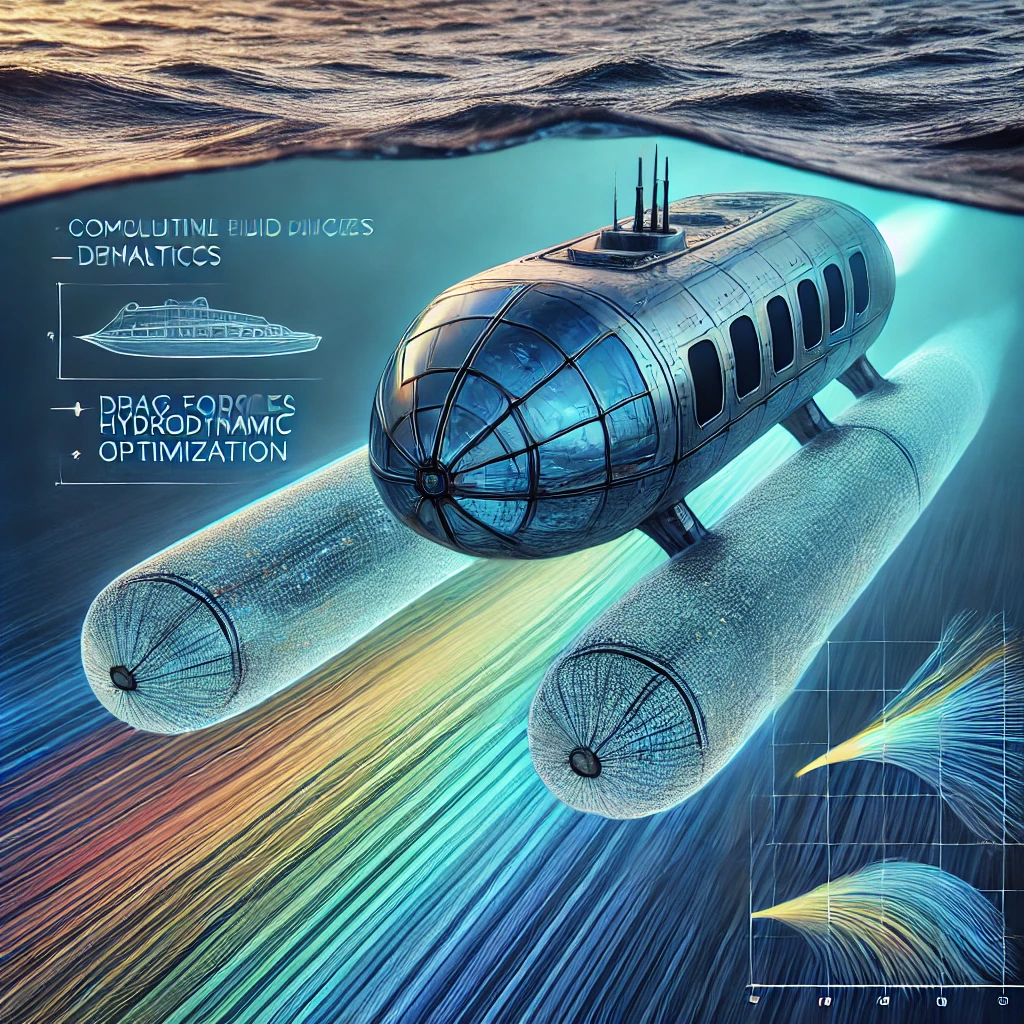

Subsea Processing

Modular skids are ideal for subsea installations, including pumping and compression systems. Their robust construction and ability to withstand extreme pressures and temperatures make them suitable for the challenging subsea environment.

Floating Production Storage and Offloading (FPSO)

In FPSO vessels, modular skids are utilized for processing hydrocarbons. Their ability to be easily transported and installed on floating vessels makes them an ideal solution for the dynamic and space-constrained environment of FPSOs.

Conclusion

Summary of Benefits and Applications

Modular process skids offer numerous advantages in terms of cost, efficiency, and safety, making them an attractive option for various industries. Their adaptability and ease of integration are particularly beneficial in ocean engineering, where they contribute to the streamlined and reliable operation of offshore facilities. The pre-fabrication and rigorous quality control associated with modular skids ensure that they meet high standards of performance and reliability. This is particularly important in harsh environments, such as those encountered in offshore operations, where equipment failure can lead to significant financial and environmental consequences.

The versatility of modular process skids is evident in their wide range of applications, from chemical processing and pharmaceuticals to food and beverage production, oil and gas refining, water treatment, and power generation. Each of these industries benefits from the modular skid’s compact design, ease of maintenance, and consistent quality, making them a preferred solution for modern industrial processes.

Future Perspectives in Ocean Engineering

As the demand for offshore oil and gas operations continues to grow, the role of modular process skid design in ocean engineering is expected to expand. Advances in skid design and fabrication techniques will further enhance their reliability and efficiency, driving their adoption in an increasing number of applications. Several key trends and future developments are anticipated:

- Enhanced Materials and Technologies: The use of advanced materials and innovative technologies will improve the durability and performance of modular skids, making them even more suitable for the extreme conditions of offshore environments.

- Integration with Digital Technologies: The integration of digital technologies, such as the Internet of Things (IoT) and advanced monitoring systems, will allow for real-time monitoring and control of modular process skids. This will lead to improved operational efficiency, predictive maintenance, and reduced downtime.

- Customization and Standardization: While modular skids offer a high degree of customization, there is also a trend towards standardization to reduce costs and simplify integration. Future designs may balance these two aspects to offer both tailored solutions and standardized modules that can be quickly deployed.

- Sustainability and Environmental Impact: As environmental regulations become more stringent, modular skid designs will need to incorporate features that minimize their environmental impact. This includes energy-efficient designs, reduced emissions, and the ability to process and treat waste more effectively.

- Collaboration and Partnerships: Increased collaboration between engineering firms, skid manufacturers, and end-users will lead to the development of more innovative and effective solutions. Partnerships can facilitate the sharing of knowledge and resources, driving advancements in modular skid technology.

- Expansion into New Markets: Beyond traditional applications, modular process skids may find new uses in emerging markets such as renewable energy and marine biology. For example, they could be used in offshore wind farms or for processing seawater in desalination plants.

In conclusion, modular process skid design in ocean engineering is set to play a pivotal role in the future of offshore operations. The continued evolution of skid technology, combined with the growing need for efficient and reliable processing solutions in challenging environments, underscores the importance of modular skids. By embracing innovation and focusing on sustainability, the industry can ensure that modular process skids remain at the forefront of ocean engineering advancements, driving progress and supporting the sustainable development of offshore resources.