Diaphragm valves play a vital role in numerous industrial processes, particularly in situations demanding meticulous management of fluid flow. These valves feature a flexible diaphragm that acts as a barrier between the valve body and the controlled fluid. Available in various sizes, materials, and configurations, diaphragm valves offer unparalleled control. This article provides a comprehensive overview of diaphragm valves, covering their fundamental principles, construction, operational mechanisms, diverse types, versatile applications, notable advantages and disadvantages, as well as essential maintenance considerations.

Exploring the Construction and Functioning of Diaphragm Valves

Diaphragm valves are composed of a valve body, a bonnet, and a flexible diaphragm. The diaphragm, typically made of materials like rubber or neoprene, is designed to be flexible enough to deform when pressure is applied, allowing fluid to flow through the valve. On the other hand, when the valve is closed, the diaphragm forms a tight seal against the valve body, preventing any fluid from passing through.

To control the operation of a diaphragm valve, there is a mechanism that applies pressure to the diaphragm, determining whether the valve is open or closed. The most common types of mechanisms used are handwheels and actuators. Handwheels are connected to a stem, which is then linked to the diaphragm. By rotating the handwheel, the diaphragm is moved either upward or downward, resulting in the valve opening or closing accordingly. Actuators, on the other hand, are more sophisticated and can be controlled by electrical signals or pneumatic pressure. They are commonly used in automated control systems to regulate diaphragm valve operations.

Parts of a Diaphragm Valve

A diaphragm valve consists of several key components that work together to control fluid flow effectively:

- Valve Body: This component forms the main structure of the diaphragm valve, providing strength and rigidity. It houses the other components and ensures the integrity of the valve.

- Bonnet: Positioned at the top of the diaphragm valve, the bonnet serves as a cover. It helps protect the internal components and provides a secure enclosure for the valve assembly.

- Diaphragm: The diaphragm is a crucial element of the valve. It is typically made of flexible materials like rubber or elastomers and is responsible for separating the valve body from the fluid being controlled. The diaphragm deforms under pressure, enabling or obstructing the flow of fluid through the valve.

- Compressor: The compressor plays a vital role in operating the diaphragm. It exerts pressure on the diaphragm, causing it to move and control the fluid flow. The compressor can be manual or automated, depending on the specific application and control requirements.

- Stem: The stem is a rod-like component that connects the diaphragm to the actuator or compressor. In some diaphragm valves, the stem can be either rising or non-rising, indicating whether it physically moves upward or remains stationary during valve operation.

- Actuator: The actuator is a mechanism that controls the movement of the diaphragm. It can be operated manually, electrically, pneumatically, hydraulically, or even thermally, depending on the application and the desired level of automation. Actuators provide precise and reliable control over the diaphragm, allowing for efficient fluid regulation.

- Position Indicators: These indicators are additional features that provide visual or electronic feedback on the position of the diaphragm valve. They assist in monitoring and controlling the valve’s operation, ensuring accurate and consistent performance.

Together, these components work harmoniously to enable the diaphragm valve to perform its essential function of regulating fluid flow in various industrial applications.

Types and Varieties of Diaphragm Valves

Diaphragm valves come in various types, each distinguished by its distinct design and purpose. These types are primarily categorized based on the construction of the valve body and the design of the diaphragm.

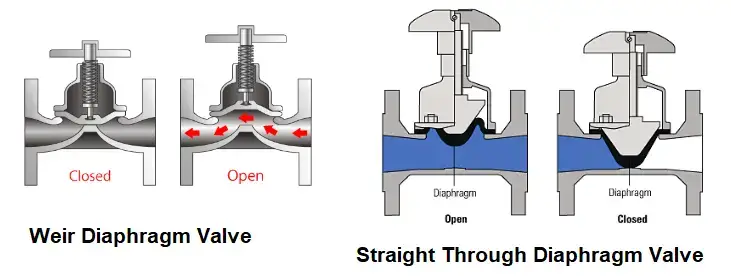

Let’s explore two main types: Weir diaphragm valves and Straight-through diaphragm valves.

Weir Diaphragm Valves

Weir diaphragm valves are specifically engineered with a raised lip, known as a weir, encircling the edge of the valve body. The diaphragm is strategically positioned over the weir, and when the valve is opened, the fluid gracefully passes over the weir and proceeds through the valve. This design is widely recognized and highly favored among diaphragm valves. Weir diaphragm valves are commonly chosen for applications involving gases, as well as for handling clean and uniformly composed liquids. Their popularity stems from their ability to ensure smooth and controlled fluid flow in these particular scenarios.

The preference for weir diaphragm valves in handling gases arises from their ability to maintain tight shut-off capabilities. The design ensures a secure seal when the valve is closed, preventing any unwanted leakage of gas.

Straight through Diaphragm Valves

Straight-through diaphragm valves feature a flat-bottom valve body, with the diaphragm directly positioned over the fluid flow path. These valves are specifically suited for handling semi-solid media like slurries, sludges, and viscous fluids. They are known for their short service life but are preferred in applications where efficient flow of such materials is required. By having the diaphragm directly in the flow path, straight-through diaphragm valves facilitate unobstructed movement of thick or sticky substances, ensuring effective fluid control in challenging environments.

Based on their applications, the following types of diaphragms are popular among industries:

Sanitary Diaphragm Valves:

Sanitary diaphragm valves are extensively employed in industries that require a high level of fluid purity and cleanliness. These valves find wide application in winemaking, dairy, beverages, food processing, and pharmaceutical processing. By creating an aseptic environment for the flowing media, these valves effectively prevent the growth of bacteria, fungi, and viruses, ensuring optimal hygiene standards.

Biotech Valves:

Biotech valves are specialized diaphragm valves designed to handle fluids containing microorganisms, cells, and other biological matter. These valves are commonly utilized in pipelines associated with bioreactors, fermenters, filtration, and chromatography skids, predominantly found in biotechnology fields such as medicine, agriculture, pharmaceuticals, and food science.

Hygienic Valves

Hygienic valves are specifically engineered diaphragm valves to prevent fluid stagnation, making them ideal for handling products intended for human consumption. These valves are extensively employed in the food and beverage industries, where maintaining high levels of hygiene and preventing contamination are of utmost importance.

Process Valves:

Process valves are diaphragm valves utilized for regulating the flow rates of liquid and gaseous fluids in various process industries. They play a crucial role in maintaining precise control over fluid flows in industrial operations.

Zero Static Valves:

Zero static valves, primarily used in the pharmaceutical industry, are multi-port valves designed to facilitate the transfer, drainage, sampling, or diversion of process fluids without causing significant impact on critical systems like Water for Injection (WFI) or Purified Water.

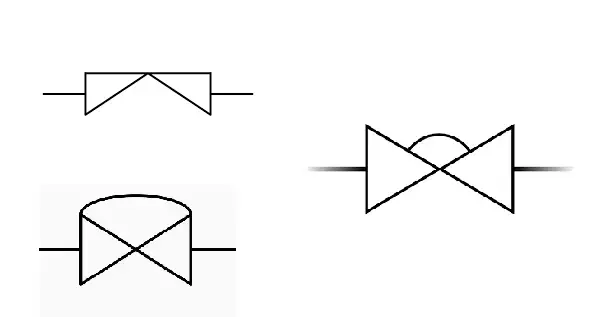

Diaphragm Valve Symbol:

The specific symbol used to represent a diaphragm valve may vary depending on the applicable standards and the specific application. Generally, diaphragm valves can be denoted using various symbols that are recognized within the industry.

Materials for Construction of Diaphragm Valves

Diaphragm valves offer a diverse range of construction materials to meet specific application requirements. The following are some of the most commonly used materials:

- PVC (Polyvinyl Chloride): PVC is a thermoplastic material suitable for low-pressure applications. It offers good resistance to various chemicals but has a limited temperature range and may become brittle over time.

- CPVC (Chlorinated Polyvinyl Chloride): CPVC is similar to PVC but exhibits superior resistance to high temperatures and corrosive chemicals. It is commonly employed in industrial settings that demand enhanced chemical resistance.

- PP (Polypropylene): PP is a thermoplastic material known for its excellent resistance to a wide range of chemicals. It finds applications in handling corrosive liquids and gases.

- PVDF (Polyvinylidene Fluoride): PVDF is a thermoplastic material with exceptional resistance to chemicals and high temperatures. It is well-suited for applications involving highly corrosive and aggressive fluids.

- Stainless Steel: Stainless steel is a durable and corrosion-resistant material favored for high-pressure and high-temperature applications. It comes in various grades and alloys to cater to specific needs.

- Hastelloy: Hastelloy is a nickel-based alloy recognized for its exceptional corrosion resistance and chemical durability. It is commonly chosen for applications involving highly corrosive and aggressive fluids.

- Titanium: Titanium is a lightweight yet sturdy and corrosion-resistant metal. It is preferred for applications with highly corrosive and aggressive fluids, offering excellent performance and a high strength-to-weight ratio.

Apart from these, diaphragm valves can also be crafted from materials such as brass, bronze, cast iron, ductile iron, cast steel, and other metals, depending on the specific demands of the application. The selection of the appropriate construction material is crucial to ensure optimal performance, longevity, and compatibility with the fluids being handled.

Choosing the Right Diaphragm Valve: Key Considerations for Selection

Choosing the right diaphragm valve requires careful consideration of various important parameters to ensure its suitability for the specific application. Here are some crucial factors to take into account during the selection process:

- Valve Size: Consider the flow rate and pressure requirements of the application to determine the appropriate valve size. Diaphragm valves are available in a range of sizes, from small-scale laboratory valves to large industrial ones.

- Materials of Construction: Select materials based on the application’s needs, including the nature of the handled fluid, temperature, pressure, and potential corrosive or chemical properties.

- Diaphragm Material: Choose the diaphragm material based on compatibility with the handled fluid, as well as the temperature and pressure conditions. Common options include rubber, PTFE, and various plastics.

- Valve Actuation: Determine whether manual operation or automation is required based on factors such as frequency of operation and precision control needs.

- End Connections: Consider the specific piping configuration and select the appropriate end connections for the diaphragm valve, such as threaded, flanged, or tri-clamp connections.

- Flow Control: Assess the application’s flow control requirements and choose a diaphragm valve designed for either precise flow control or simple on/off applications.

- Maintenance and Repair: Evaluate the ease of maintenance and repair. Opt for diaphragm valves that are easy to disassemble and reassemble for cleaning and maintenance purposes, and ensure that replacement parts are readily available.

By carefully considering these parameters, you can make an informed decision and select a diaphragm valve that perfectly aligns with your application’s specific requirements, ensuring optimal performance and longevity.

Various Applications of Diaphragm Valves

Diaphragm valves find widespread use across diverse industries, including pharmaceuticals, food and beverage, chemical processing, and water treatment. These valves are particularly employed in applications requiring precise control over fluid flow and the minimization of fluid contamination. Some of the common applications of diaphragm valves include:

Pharmaceutical Manufacturing: Diaphragm valves play a critical role in pharmaceutical manufacturing, facilitating precise fluid flow control during the production of drugs and other pharmaceutical products. They ensure the controlled movement of liquids and gases, preventing contamination of the product by foreign particles.

Food and Beverage Processing: Diaphragm valves are essential in the food and beverage industry, enabling meticulous control over fluid flow during the production of consumable products. These valves ensure the precise regulation of liquid and gas flow, safeguarding the product against bacteria and other contaminants.

Chemical Processing: Diaphragm valves find extensive application in chemical processing, where they effectively regulate the flow of chemicals during the production of various chemical compounds. They enable the controlled flow of highly corrosive and toxic substances, minimizing the risk of environmental contamination and ensuring the safety of personnel.

Water Treatment: Diaphragm valves are integral components of water treatment plants, providing control over the flow of water and other liquids during the treatment process. These valves enable precise regulation of chemical and additive flow, preventing contamination of the water supply and ensuring the delivery of clean and safe water.

In summary, diaphragm valves serve crucial roles in a wide range of industries, ensuring accurate fluid control and preventing contamination in applications where precise flow regulation is essential.

Advantages and Disadvantages of these Valves

Advantages

Diaphragm valves possess several advantages over alternative valve types, including:

- Precise Flow Control: Diaphragm valves excel at providing precise control over fluid flow. Their design allows for accurate regulation of flow rates, making them well-suited for applications where maintaining specific flow rates is critical.

- Low Maintenance: Diaphragm valves are known for their simplicity and ease of maintenance. They typically require minimal maintenance and have fewer moving parts compared to other valve types. This ease of maintenance translates into cost savings and reduced downtime.

- Corrosion Resistance: Diaphragm valves are available in a wide range of materials, including corrosion-resistant options such as plastics and stainless steel. This variety of materials allows for compatibility with different fluids and protects against corrosion, ensuring longevity and reliability in diverse operating environments.

- Minimal Pressure Drop: Diaphragm valves exhibit minimal pressure drop across the valve, enabling efficient flow without significant loss in pressure. This characteristic makes them favorable for applications where high flow rates or low pressure differentials are desired, promoting energy efficiency and system performance.

By combining precise flow control, low maintenance requirements, corrosion resistance, and minimal pressure drop, diaphragm valves offer an advantageous solution for various industries and applications, contributing to enhanced operational efficiency and fluid handling capabilities.

Disadvantages

Despite their advantages, diaphragm valves do have certain limitations and drawbacks, including:

- Limited Temperature Range: Diaphragm valves may not be suitable for high-temperature applications. The diaphragm material used in these valves may degrade or lose its functionality at elevated temperatures, potentially compromising the valve’s performance and reliability.

- Limited Pressure Range: Diaphragm valves may have limitations in handling high-pressure conditions. Excessive pressure can cause the diaphragm to rupture or fail, leading to leakage and potential system malfunctions.

- Limited Flow Capacity: Diaphragm valves may not be the best choice for applications that require high flow rates. The valve body design and the flexible nature of the diaphragm can impose limitations on the maximum flow capacity. In situations where there are high flow demands, the valve body may become obstructed or the diaphragm may rupture, affecting the valve’s ability to control fluid flow accurately.

It is important to consider these limitations when selecting a diaphragm valve for a specific application. Assessing the temperature, pressure, and flow requirements is crucial to ensure the chosen diaphragm valve can operate within the desired parameters and provide reliable performance.

Maintenance Requirements

Diaphragm valve maintenance is often quite simple due to their low-maintenance nature. Here are some important maintenance requirements to remember:

Regular Inspection: It is critical to inspect the diaphragm valve on a regular basis to look for signs of wear, corrosion, or degradation. Concentrate on the condition of the diaphragm itself, as it is critical in controlling fluid flow. If any wear or damage is observed, the diaphragm should be changed as soon as possible to ensure optimal valve operation.

Cleaning: Periodic cleaning of the valve body is required to remove any accumulated debris, grime, or accumulation that may obstruct the valve’s proper operation. Cleaning intervals will vary depending on the application and the type of fluid being handled. To ensure effective cleaning without damaging the valve components, follow manufacturer specifications or industry best practises.

Actuator and Control Mechanism Maintenance: If the diaphragm valve has an actuator or control mechanism, these components must be inspected and tested on a regular basis to guarantee appropriate operation. Check for any indicators of malfunction or aberrant behaviour, and repair any concerns as soon as possible to maintain the valve’s overall performance and reliability.

Maintenance Schedule: It is recommended that a maintenance schedule be established based on the operating conditions and the manufacturer’s recommendations. This schedule should detail precise maintenance chores, inspection intervals, and diaphragm and other important component replacement times.

The longevity and effectiveness of the diaphragm valve can be maximised by following a regular maintenance programme that includes examination, cleaning, and component replacement as needed. For precise maintenance recommendations and procedures, it is critical to follow industry best practises and check the manufacturer’s guidelines.

Leading manufacturers of Diaphragm Valves

Several reputable manufacturers excel in producing diaphragm valves, each with their own unique product offerings and strengths. Here are some prominent manufacturers in the field:

- Gemu: It is a German company, is widely recognized for manufacturing high-quality diaphragm valves known for their durability, reliability, and precise performance. Their diverse range of valves caters to various applications with a focus on quality engineering.

- Saunders: It is a UK-based manufacturer, specializes in diaphragm valves for industries such as chemical processing, pharmaceuticals, and water treatment. Their valves are highly regarded for their outstanding performance, long service life, and ease of maintenance.

- GF Piping Systems: Headquartered in Switzerland, this company offers an extensive selection of diaphragm valves designed for industrial applications. Their valves are distinguished by their exceptional chemical resistance, user-friendly maintenance, and extended durability.

- Aquasyn: An American company that is focused on producing diaphragm valves specifically for the bio-pharmaceutical industry. Their valves are engineered to meet the high-purity demands of such applications, ensuring utmost cleanliness, reliability, and ease of maintenance.

- Alfa Laval: A Swedish company which provides a comprehensive range of diaphragm valves serving industries like food and beverage, pharmaceuticals, and chemicals. Their valves are highly regarded for their superior performance, reliability, and ease of installation.

When selecting a diaphragm valve supplier, it is essential to consider factors such as product quality, the manufacturer’s reputation, their service and support offerings, as well as the overall value for money. Evaluating your specific application requirements and comparing the offerings from these reputable manufacturers will assist in making an informed decision that best aligns with your needs.

Conclusion

Diaphragm valves are highly versatile and reliable, finding application in various industrial settings. They boast precise control over fluid flow, ease of maintenance, and a wide range of material and configuration options. Although not ideal for high-temperature or high-pressure conditions, they excel in situations demanding accurate flow control and low maintenance requirements. By comprehending the fundamental principles of diaphragm valves, including their construction, working mechanisms, types, applications, advantages, disadvantages, and maintenance needs, industry professionals can make informed choices and operate these valves effectively to cater to their specific process requirements.