ASTM A333 Gr 6 is a specific grade of low-temperature carbon steel pipe that finds its application in various industrial sectors. It is a seamless and welded carbon and alloy steel pipe designed to be used at low temperatures, typically above -50°F (-45°C). The designation “Gr 6” refers to the steel grade, which meets the standards outlined in the ASTM A333 specification. Generally, A333 Gr 6 pipes are manufactured in sizes ranging from 1/2 inches to 24 inches.

This particular steel grade is commonly utilized in industries such as oil and gas, chemical, and power generation, where service at low temperatures is necessary. The A333 Gr 6 steel is engineered to withstand brittle fracture and exhibits excellent impact toughness, making it well-suited for cold environments up to -45°C. If the application requires using A333-6 pipe material below -45°C, impact testing may be required.

Requirements to Purchase A333-Gr 6 Pipe

When purchasing ASTM A333 Gr 6 pipe from a vendor, you need to provide the following information:

- Pipe Quantity: Specify the required quantity of A333 Gr 6 pipes.

- Manufacturing Process: Indicate whether you need seamless or welded pipes.

- A333 Gr 6 Pipe Size and Wall Thickness: Specify the desired pipe size (diameter) and the wall thickness needed for your application.

- End Finish: Specify the type of end finish required, such as plain ends, beveled ends, or threaded ends.

- Specific Requirements: If you have any specific requirements, such as heat analysis or test reports, mention them to the vendor.

By providing these details, you can ensure that the vendor supplies the appropriate ASTM A333 Gr 6 pipes that meet your specific needs.

Chemical Composition of ASTM A333-6 Material

ASTM A333 Gr 6 pipe material consists of various alloying elements, including:

- Carbon: Maximum content of 0.3%

- Manganese: Content ranges from 0.29% to 1.06%

- Phosphorus: Maximum content of 0.025%

- Sulfur: Maximum content of 0.025%

- Silicon: Minimum content of 0.1%

- Nickel: Maximum content of 0.4%

- Chromium: Maximum content of 0.3%

- Copper: Maximum content of 0.4%

- Vanadium: Maximum content of 0.08%

- Columbium: Maximum content of 0.02%

- Molybdenum: Maximum content of 0.12%

These alloying elements contribute to the specific properties and characteristics of the A333 Gr 6 pipe material, ensuring its suitability for low-temperature service applications.

Mechanical properties of A333 Gr 6 Pipe Material For Low Temperature Applications

The A333 Gr 6 Pipe Material exhibits the following mechanical properties:

- Minimum Tensile Strength: 415 MPa (60 ksi)

- Minimum Yield Strength: 240 MPa (35 ksi)

- Minimum Longitudinal Elongation in 2 inches (50mm): 30%

- Minimum Transverse Elongation in 2 inches (50mm): 16.5%

These mechanical properties ensure the strength and ductility of the A333 Gr 6 pipe, making it suitable for low-temperature applications where it needs to withstand high pressures and maintain its integrity.

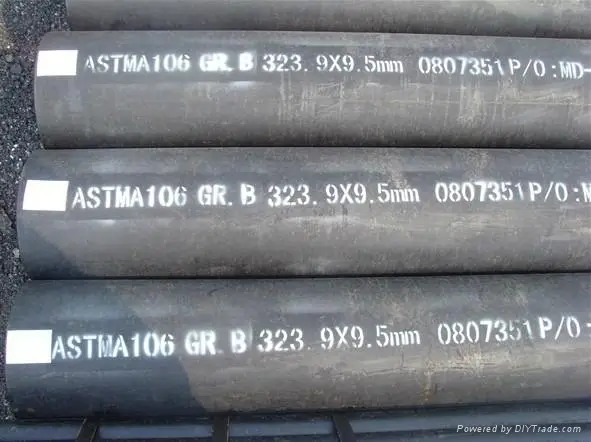

Comparing A106 Grade B and A333 Grade 6 Pipe Materials: Key Differences for Low-Temperature Applications

A106 Gr B and A333 Gr 6 are distinct grades of carbon steel pipes intended for various applications. Here are the key differences between them:

- Temperature Range: A106 Gr B pipes are designed for high-temperature and high-pressure environments, whereas A333 Gr 6 pipes are specifically meant for low-temperature applications.

- Chemical Composition: While the chemical composition of A106 Gr B and A333 Gr 6 is similar, there are slight differences in the maximum allowed values for elements such as Phosphorus, Sulfur, Chromium, and Molybdenum. A106-B material permits slightly higher ranges for these elements compared to A333-6 material.

- Mechanical Properties: Both grades exhibit comparable mechanical properties. A106 Gr B and A333 Gr 6 have a minimum tensile strength of 60,000 psi and a minimum yield strength of 35,000 psi.

- Manufacturing Method: A106 Gr B pipes are typically manufactured using the seamless method, while A333 Gr 6 pipes can be produced through either seamless or welded techniques. This represents a significant distinction between A106-B and A333-6.

Ultimately, the choice between A106 Gr B and A333 Gr 6 depends on the specific requirements of the application, particularly the anticipated temperature conditions under which the pipes will operate.

A333-6 Pipe Manufacturers

There are many manufacturers of ASTM A333 Grade 6 pipe, but some of the biggest ones include:

- Nippon Steel & Sumitomo Metal Corporation

- ArcelorMittal

- JFE Steel Corporation

- Tenaris SA

- Vallourec SA

- Tubos Reunidos SA

- United States Steel Corporation

- TPCO Enterprise Inc.

- Maharashtra Seamless Ltd.

- China Zhonghai Steel Pipe Manufacturing Corporation.

It’s worth noting that this list is not exhaustive and there are many other reputable manufacturers of ASTM A333 Grade 6 pipe.

Here are some of the biggest manufacturers of ASTM A333 Grade 6 pipe from India:

- Maharashtra Seamless Ltd.

- Jindal Saw Ltd.

- ISMT Limited

- Mukat Pipes Limited

- Ratnamani Metals & Tubes Ltd.

- U.S. Metals

- Sandvik Materials Technology India Pvt. Ltd.

- Bhushan Steel Limited

- Lloyds Line Pipes Limited

- Tubacex India Pvt. Ltd