Pipeline Stress Analysis Course for Beginners: Learn with Caesar II Online

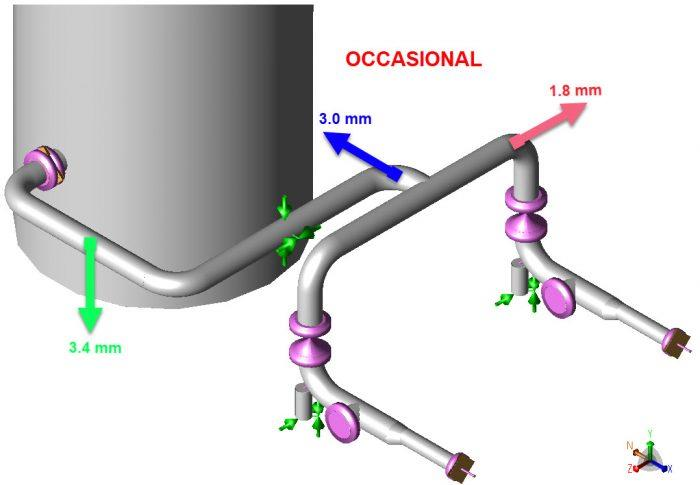

Pipeline Stress Analysis is a crucial process in assessing the mechanical behavior of pipelines under various operating conditions. It involves using specialized software like Caesar II to model and calculate stresses, strains, and deformations. This analysis helps identify potential problem areas and ensures the pipeline’s structural integrity. Pipeline Stress Analysis plays a vital role in…