A pressure switch is a device, either electronic or mechanical, that lets us know when a specific pressure level is reached. It is used in systems that need to monitor pressure. When the pressure reaches a certain level, the pressure switch turns on an electrical contact. Pressure switches find many uses in industrial and residential settings. Some common examples include furnaces, HVAC systems, and well pumps. In this article, we’ll explore how pressure switches work, the different types available, how to choose the right one, and where they are commonly used.

Understanding Pressure Switch

Pressure switches are essential devices used to keep an eye on the pressure in a system. They help control systems that use pressurized fluids by signaling when the pressure goes up or down. Depending on the system’s pressure, the device switches between ON and OFF states. These switches are widely used in various process control systems.

The pressure switch usually consists of the following components:

- A flexible and sensitive diaphragm to detect pressure changes.

- A spring to set the desired pressure points for switching ON or OFF.

- A lever that activates or deactivates the pressure switch.

- An electrical contact that connects to an external power source.

- Terminals to link the external power source to the electrical contacts.

Types of Pressure Switches

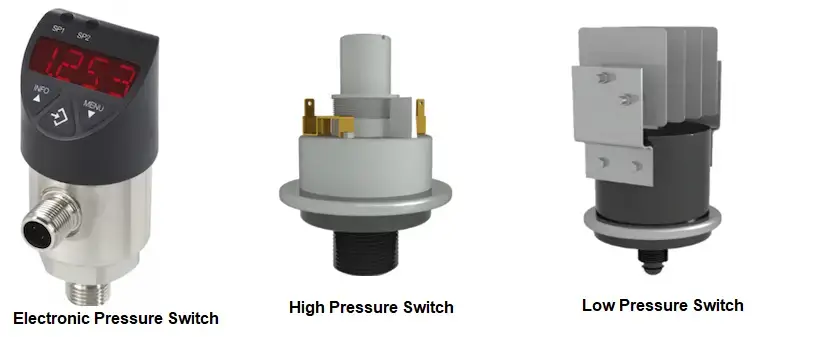

Pressure switches can be divided into two main types based on their working: Mechanical Pressure Switches and Electronic Pressure Switches.

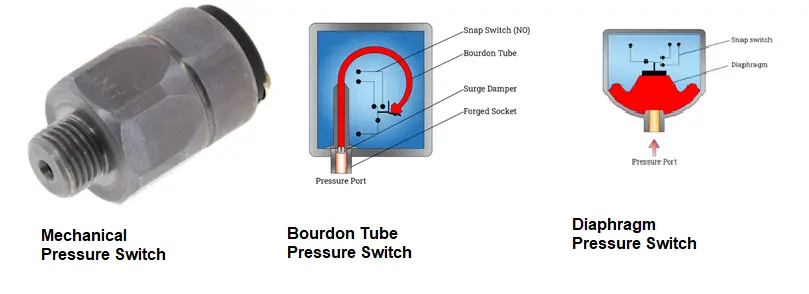

- Mechanical Pressure Switches: These switches are sturdy and straightforward in design. They use a combination of a spring and a diaphragm or piston to control the pressure that triggers the switch. The spring’s force counteracts the inlet pressure, and a set screw or knob adjusts the spring’s tension. This tension determines the set pressure at which the switch makes an electric contact, activating the device. When the pressure drops, the pressure switch returns to its original state.

- Electronic Pressure Switches: These switches are more sophisticated and use electronic components to monitor pressure. They provide precise pressure measurements and offer digital displays for easy monitoring. Electronic pressure switches often have programmable set points and hysteresis, which is the difference between the switch point and reset point, typically expressed as a percentage.

Mechanical pressure switches are better suited for handling high voltages and amperages compared to electronic ones. They can have three types of contacts: normally open (NO), normally closed (NC), and changeover (SPDT), which can perform both NO and NC operations.

Types of Mechanical switches

Mechanical pressure switches are a type of electromechanical pressure switches. They come in different types based on the pressure-sensing element they use:

- Bourdon Tube Pressure Switch: This switch employs a flexible tube to sense pressure changes.

- Diaphragm Pressure Switch: It utilizes a diaphragm to detect pressure variations.

- Piston Pressure Switch: This type uses a piston mechanism for pressure sensing.

- Differential Pressure Switch: It relies on the difference in pressure between two points for its operation.

- Snap Disc Pressure Switch: This switch incorporates two metal discs to sense pressure changes.

Each of these mechanical pressure switches works in a slightly different way to monitor and respond to pressure fluctuations in various systems.

Electronic Pressure Switch

An electronic pressure switch uses an electrical pressure sensor (pressure transducer) to measure changes in pressure. It displays the switching function digitally, making it easy to see the pressure readings. The set pressure can be adjusted by the manufacturer or programmed on-site. This type of pressure switch is very versatile because you can adjust the switch point, delay time, hysteresis, and output signals to suit different applications. Electronic pressure switches are solid-state switches suitable for automated and controlled equipment. They operate using electrical parameters like resistance and capacitance.

There are two types of electronic pressure switches based on pressure handling capability:

- High-Pressure Switches: Designed to handle pressure ranging from 1 PSIG to 10,000 PSIG.

- Low-Pressure Switches: Sensitive to small pressure fluctuations and respond to low-pressure levels.

Working of a Power Switch

As mentioned earlier, pressure switches can work either mechanically or electronically. Let’s focus on the mechanical operation principle.

In a mechanical pressure switch, the pressure of the fluid entering the switch pushes a piston against a spring with a known resistance force. The spring is designed in such a way that the piston will move only when a specific pressure level is reached. Once the pressure reaches this predetermined point, the piston activates a micro-switch. This causes the micro-switch to move from a normally closed (NC) position to a normally open (NO) position using an operating pin and trip button. This change in the micro-switch position signals that the desired pressure has been achieved.

Selection Criteria for Pressure Switches

When selecting a pressure switch, several factors should be considered:

- Process Fluid Type: The materials of wetted parts must be compatible with the process fluid used, such as hydraulic oil, water, air, etc.

- Working Pressure Range: The pressure switch should be able to handle the entire working pressure range, and the design should match the type of pressure (positive or vacuum).

- Temperature: The working temperature range should be taken into account as it can affect the pressure switch’s effectiveness. Some switches may need readjustment for higher temperatures.

- Repeatability: Accuracy is crucial, and pressure switches should produce consistent and precise results in each repetition.

- Switching Function: Consider the type of switching function needed, such as SPST, SPDT, DPST, DPDT, etc.

- Hysteresis: The difference between the switch point and reset point, known as hysteresis, should be predecided based on the application’s requirements.

- Service Life: The number of times the switch can activate or deactivate before failure should be considered. Electronic pressure switches generally have a longer service life due to fewer moving parts.

- End Connection Fittings: Ensure that the pressure switch’s end connection is compatible with the process port connection.

- Certification and Approval: Check for national and international certifications and approvals, such as UL, CSA, FM, CE, etc., to ensure the quality of the pressure switch.

By considering these factors, you can make an informed decision when selecting the most suitable pressure switch for your application.